At VAK KIMSA we are pioneers in the development, application and manufacturing of in line mixers.

Mixing has always been a basic operation in the industry. Since the origins of VAK KIMSA, we have always sought excellence in this operation. When agitators do not provide optimal results, in line mixers realize this excellence.

In line mixers perform the functions of dissolution and dispersion of solids in liquids, emulsion, dilution and mixing of liquids, which are also typical of agitators.

Mixing in line has many advantages over the “classic” system of mixing by agitation, although it does not necessarily replace it, but complements it depending on the process to be carried out.

VISCOVAK for the manufacture of baby food products based on flours and starches. Food Industry.

LIVAK in the Chemical Industry.

VISCOVAK for homogeneous mixing of thickening and texturizing solids, such as xanthan, pectin, agar, carrageenan, carbomer, cellulose, etc. Food and Cosmetics Industry.

ALVAK for mixing excipients and active ingredients. Pharmaceutical Industry.

Any mixing process that requires very long stirring times or very high power, presents a significant mixing difficulty or requires a high-quality final product will require the use of an in line mixer.

With VAK KIMSA, S.A. in line mixers you will obtain excellent products: no lumps, no air, very fine and very stable. As well as optimal processes: batch flexibility, deposits without solids adherence, total dissolution of hygroscopic solids and continuous dilutions.

Definition

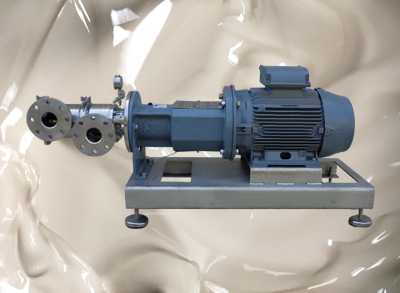

The inline mixer is the pipe-interleaved dynamic device used for mixing processes.

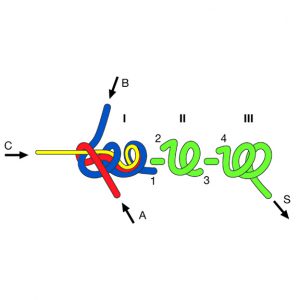

[fvplayer id=”1″]

Simulation of the behaviour of the product as it passes through the ALVAK, LIVAK, VISCOVAK and JETMIXVAK in line mixing head.

Advantages

The advantages distinguish us from other designs and technologies:

Constructive advantages

VISCOVAK for homogeneous mixing of thickening and texturizing solids, such as xanthan, pectin, agar, carrageenan, carbomer, cellulose, etc. Food and cosmetics industry.

VISCOVAK for the direct aspiration of solids from bags or drums, without the need to overturn the bag or drum, with the main advantage of avoiding the formation of dust clouds.

Feeding of powdered solids to the hopper of the ALVAK in-line mixer and mixing by recirculation on an external tank, complete mixing plant.

Process advantages

Deposits free of solids adhered to their walls, by the incorporation of solids directly to the mixer head in line ALVAK and VISCOVAK.

Addition of solids to the hopper of the mixer ALVAK and VISCOVAK.

Characteristics

In-line mixers for all processes and productions:

In-line mixer ALVAK with hopper DOSIVAK.

Feeding of solids and liquids to the hopper of the ALVAK mixer in the chemical industry.

| RANGE OF APPLICATION | ALVAK | VISCOVAK | JETMIXVAK | LIVAK | |

| Solid + Liquid |

Solids directly to the mixing head |

X | X | ||

| Solids to the tank | X | X | |||

| Liquid + Liquid | X | ||||

| Concentration of solids (%) | ≤ 80 | ≤ 80 | ≤ 80 | ≤ 80 | |

| Viscosity | Medium-Low | High | Medium-Low | High-Medium-Low | |

| Solid addition flow (kg/h) | ≤ 15.000 | ≤ 8.000 | |||

| Mixing flow (l/h) | ≤ 90.000 | ≤ 60.000 | ≤ 60.000 | ≤ 90.000 | |