VAK KIMSA manufactures agitators, in-line mixers and complete mixing plants. Since 1972 we offer global solutions to solid-liquid and liquid-liquid mixing processes for the food, chemical, cosmetics, pharmaceutical and biotechnology industries.

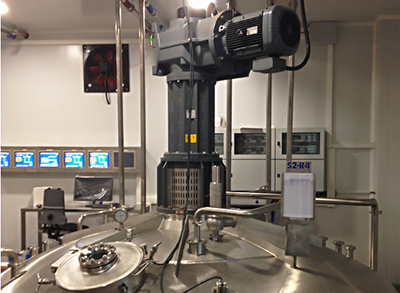

Agitator for the manufacturing of high viscosity cosmetic products.

Installation of agitators for the Food Industry.

Agitator with TRIVAK blades for dissolution.

Process Warranty and Mechanical Warranty

In VAK KIMSA we perform concurrent engineering in process engineering and product engineeringfor our wide range of agitators. Our Know How in mixing processes allows us to ensure the selection of the best agitator to meet your manufacturing process. We offer standard agitators with customized solutions.

For those applications that require it, we carry out simulation studies of the mixing process with ANSYS CFX and we have a pilot plant, as well as the technical capacity to scale up the results to the industrial equipment.

A 50-year track record in the manufacture and application of agitators makes us worthy of your trust.

Agitators for yeast maintenance.

Characteristics

The widest range of agitators on the market

- Impellers TRILIGHT, TRIVAK, ALABNET, ALABNET AXIAL, DOUBLE FLOW, ANCORA, ANCORA HELICOIDAL, TURBVAK, MULTVAK, MULFOLIVAK, COWLES, …

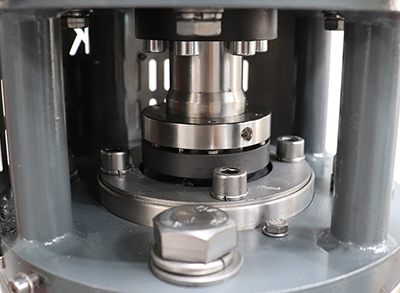

- Bearing boxes TD0, HT, TK, TK-TC.

- Mixing, dissolution, dispersion, emulsion, keeping in suspension, homogenization, thermal exchange…

- Power: 0.18 to 250 kW.

- Sealing : lip seal, stuffing box; single, double, dry or lubricated mechanical seal.

- Industrial, sanitary or aseptic.

- Design according to EHEDG and 3A.

- Safety Directive 2006/42/CE.

- ATEX Directive.

Manufacturing

To guarantee a good finish, to respect the quality procedures and to fulfill the delivery times, are maximums of our manufacturing department.

- ERP integrated management system with MRP requirements calculation.

- Own machining workshop: lathes, milling, welding, laser cutting, notching machine, ….

- First quality raw materials from approved suppliers.

- 100% quality control of the equipment.

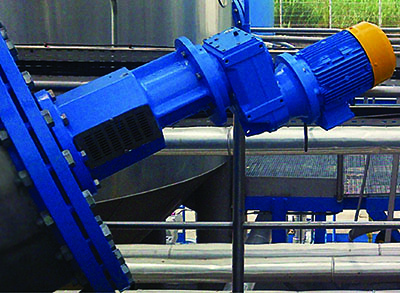

Agitators for mixing solids and liquids.

Agitators with COWLES impeller for dispersion.

Commissioning and technical assistance

A correct start-up for agitators and mixers that require it is vital to get the maximum performance from day one. At VAK KIMSA we know that.

Training

During commissioning, we offer training of the technicians and operators responsible for the use of the equipment.

Agitators with COWLES impeller for dispersion.

Commissioning and technical assistance

A correct start-up for agitators and mixers that require it is vital to get the maximum performance from day one. At VAK KIMSA we know that.

Training

During commissioning, we offer training of the technicians and operators responsible for the use of the equipment.