The best selection for your process conditions

The right sealing system depends on the product, the pressure and temperature of the process, as well as the speed of the agitator.

A large number of options are possible to cover all needs: lip seal, stuffing box, single mechanical seal, double mechanical seal, dry, lubricated, …

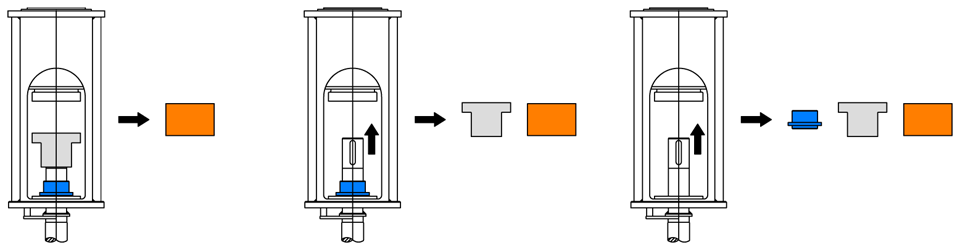

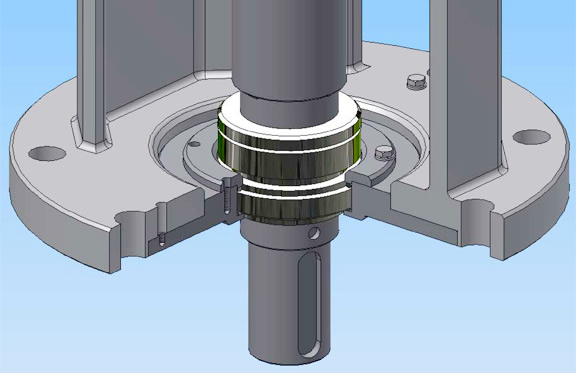

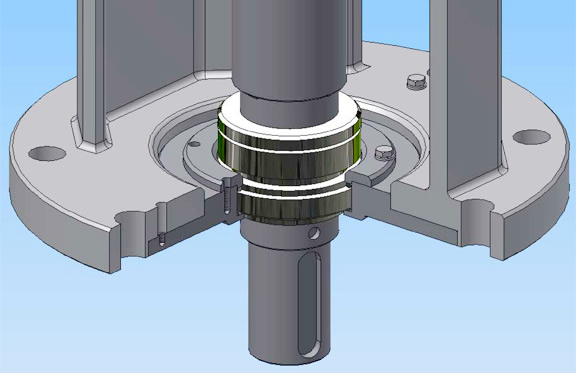

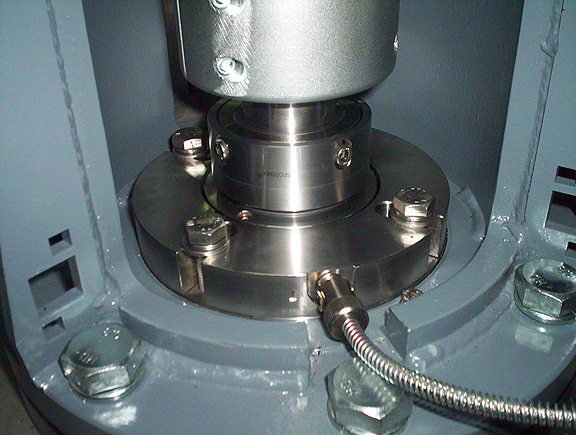

Quick disassembly of the mechanical seal

| LIP SEAL | ||

|

||

| Lubricated | Pressure (bar) | 0 ÷ 10 |

| Max. temp. (ºC) | 250 | |

| Max. speed (m/s) | 20 | |

| Dry | Pressure (bar) | 0 ÷ 6 |

| Max. temp. (ºC) | 130 | |

| Max. speed (m/s) | 10 | |

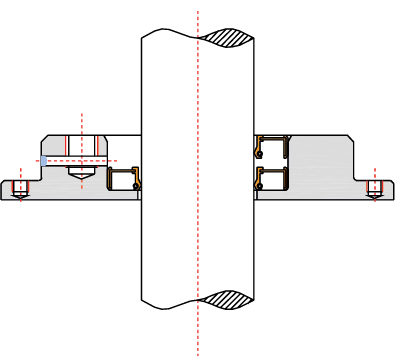

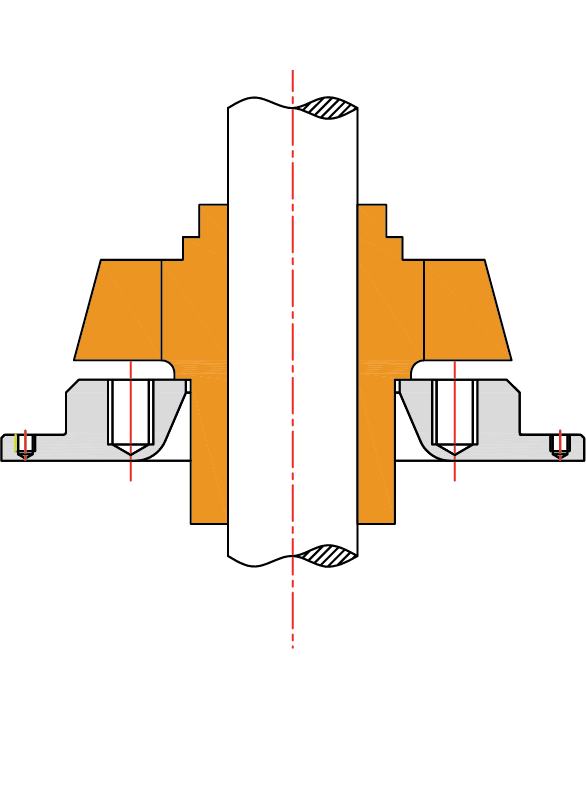

| STUFFING BOX | ||

|

||

| Lubricated | Pressure (bar) | 0 ÷ 10 |

| Max. temp. (ºC) | 250 | |

| Max. speed (m/s) | 20 | |

| Dry | Pressure (bar) | 0 ÷ 6 |

| Max. temp. (ºC) | 130 | |

| Max. speed (m/s) | 10 | |

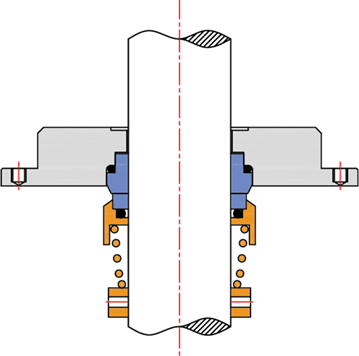

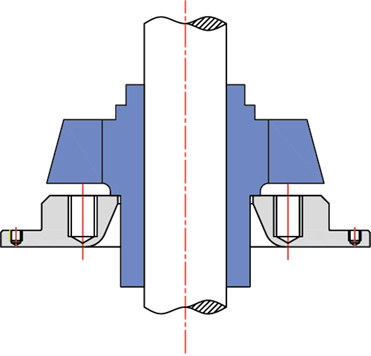

| SINGLE MECHANICAL SEAL UNBALANCED | |||

|

|

||

| + Stuffing box | |||

| Lubricated | Pressure (bar) | -1 ÷ 10 | -1 ÷ 10 |

| Max. temp. (ºC) | 200 | 200 | |

| Max. speed (m/s) | 10 | 10 | |

Single dry mechanical seal

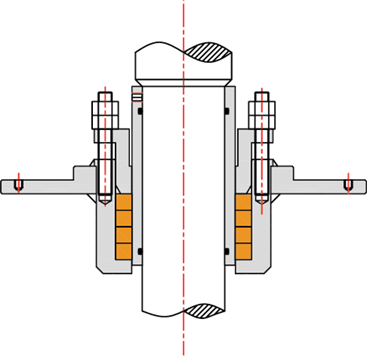

| SINGLE MECHANICAL SEAL BALANCED | ||||

|

|

|

||

| Cartridge | Flushing box | |||

| Lubricated | Pressure (bar) | Not available | -1 ÷ 25 | -1 ÷ 15 |

| Max. temp. (ºC) | 250 | 200 | ||

| Max. speed (m/s) | 12 | 10 | ||

| Dry | Pressure (bar) | -1 ÷ 4 | -1 ÷ 6 | Not available |

| Max. temp. (ºC) | 150 | 150 | ||

| Max. speed (m/s) | 3 | 3 | ||

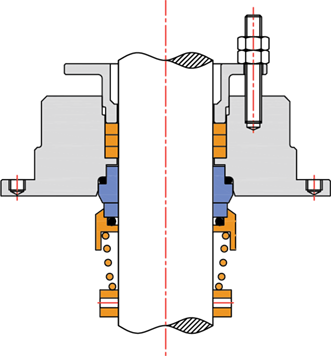

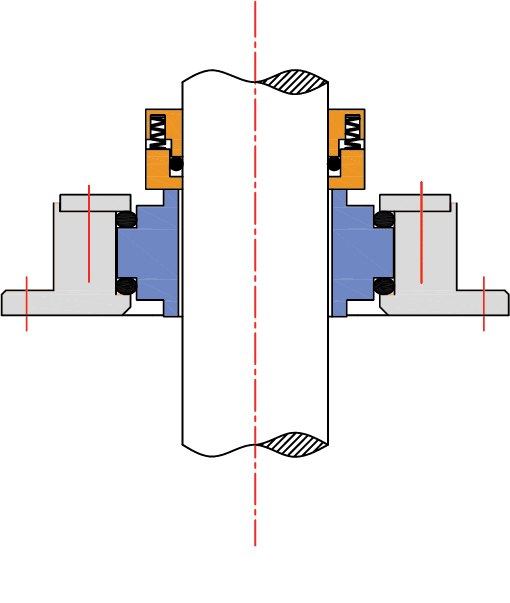

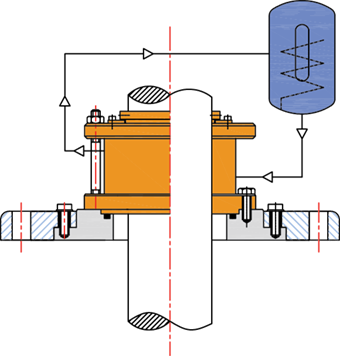

Lubricated double mechanical seal

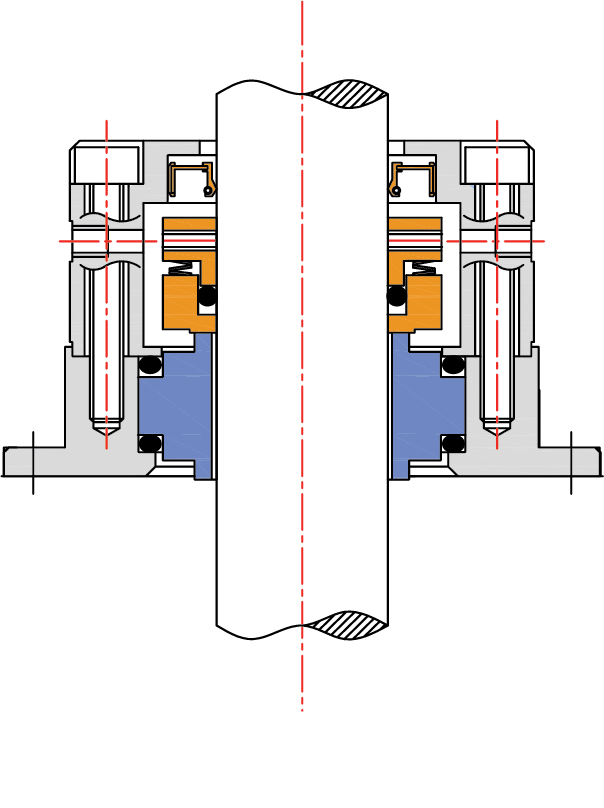

| DOUBLE MECHANICAL SEAL | |||

|

|

||

| Cartridge | Flushing box | ||

| Lubricated | Pressure (bar) | -1 ÷ 25 | -1 ÷ 75 |

| Max. temp. (ºC) | 250 | 250 | |

| Max. speed (m/s) | 10 | 10 | |

| Dry | Pressure (bar) | -1 ÷ 6 | Not available |

| Max. temp. (ºC) | 150 | ||

| Max. speed (m/s) | 3 | ||