Our Know How

Our Know How

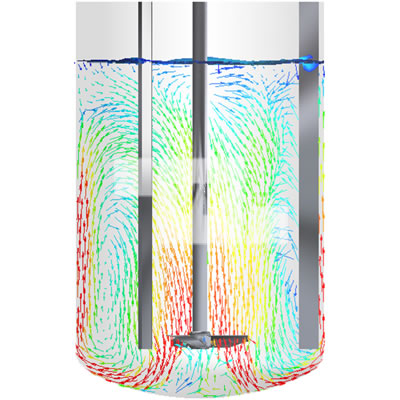

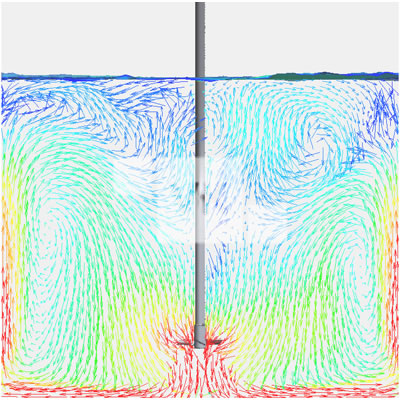

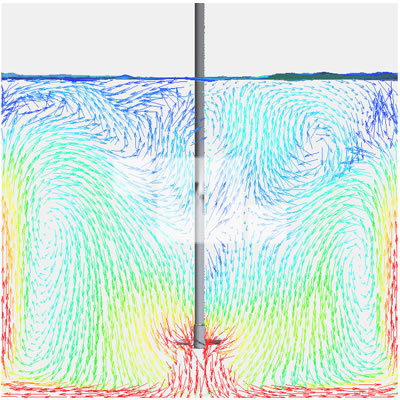

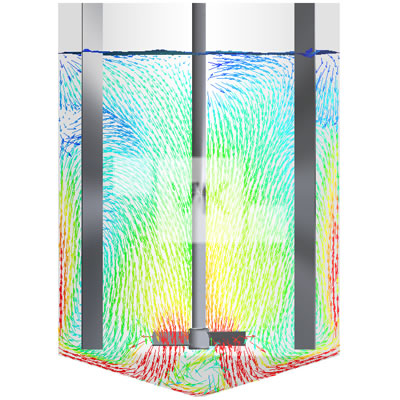

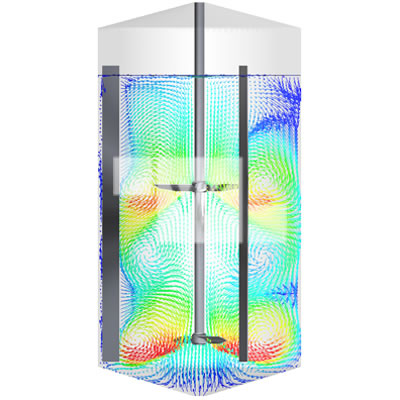

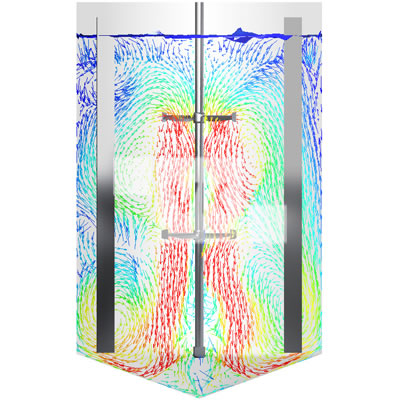

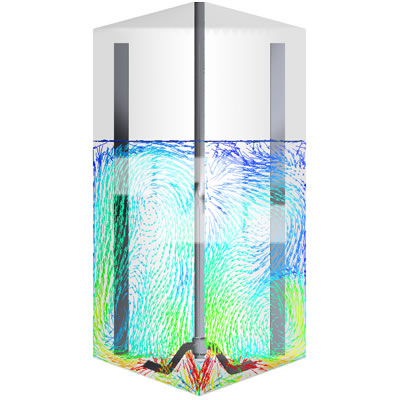

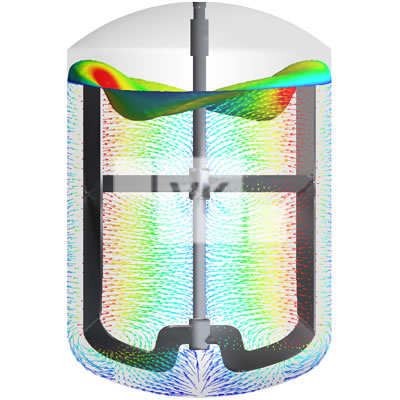

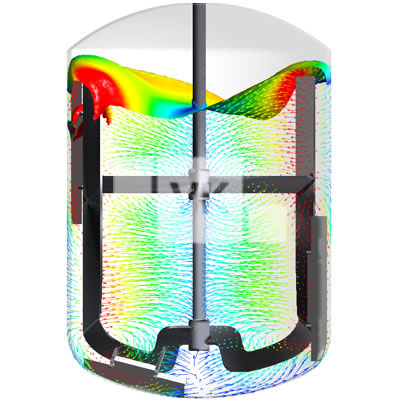

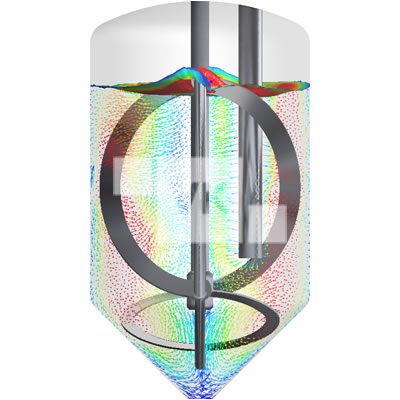

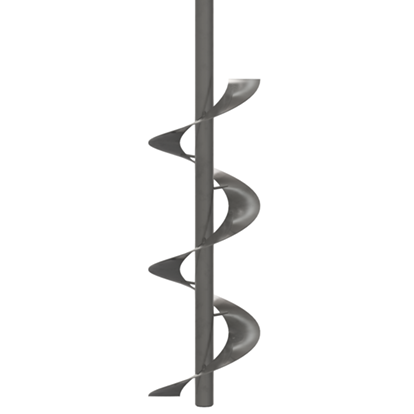

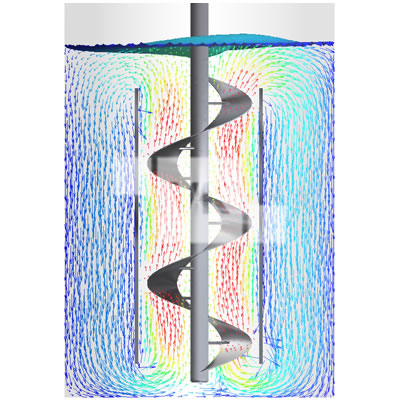

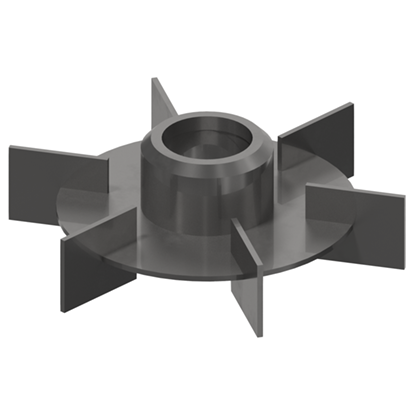

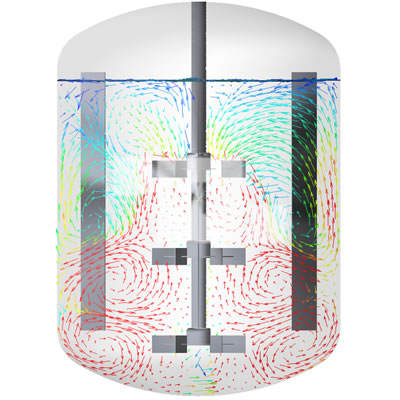

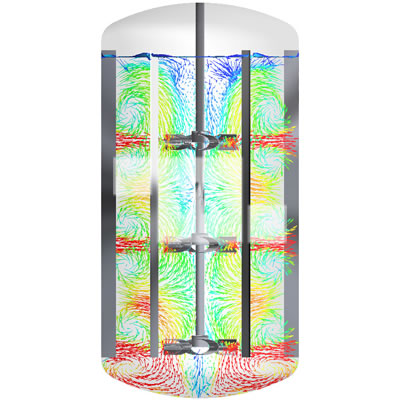

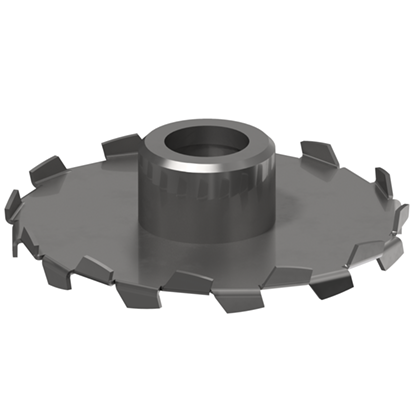

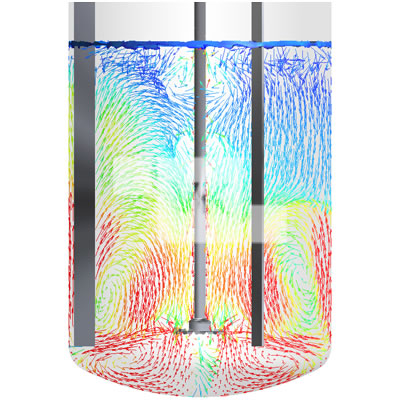

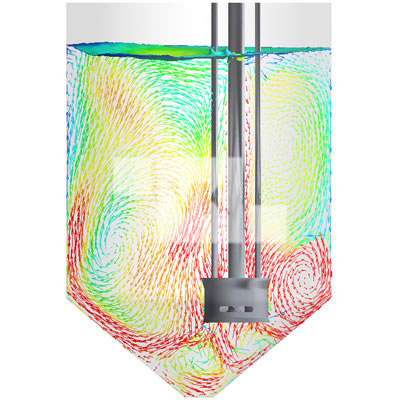

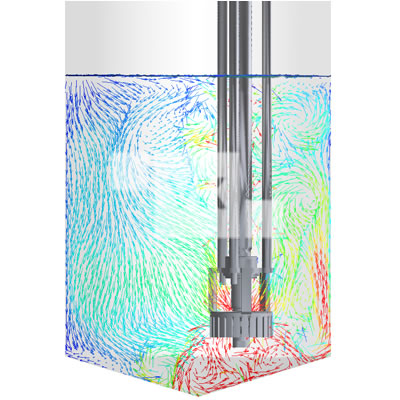

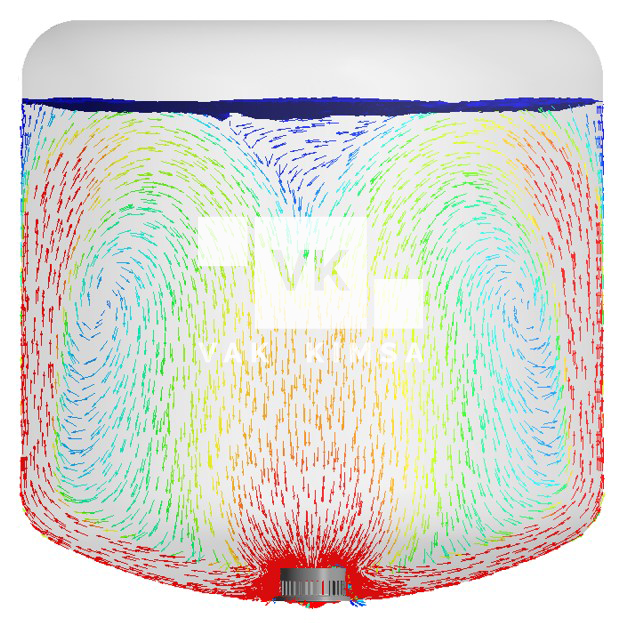

Knowing how to apply the ideal impeller to each process, selecting the right speed and optimizing to the maximum is our mission. Our experience, based on the resolution of thousands of cases, allows us to guarantee the application of our products to give you the best solution in your processes..

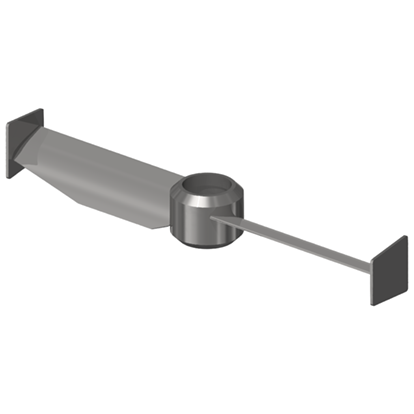

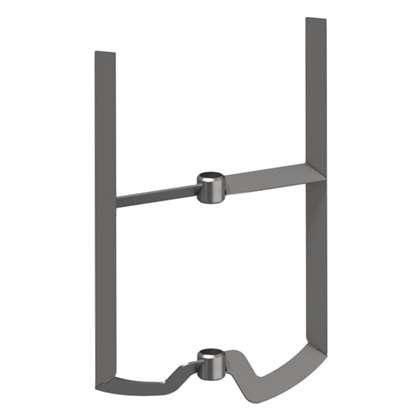

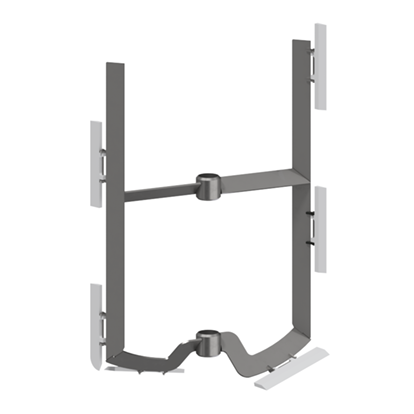

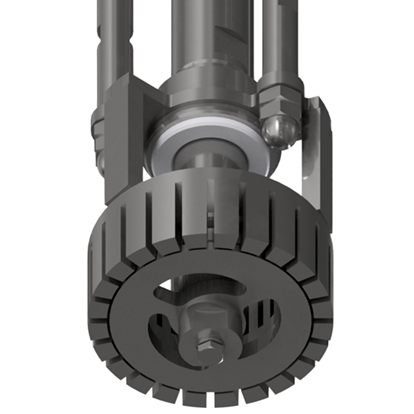

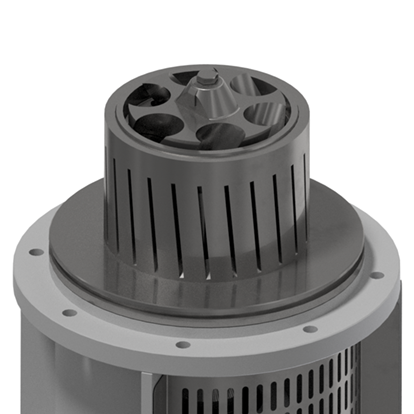

Standard designs for an adapted response to all mixing processes. All our impellers are perfectly characterized in number of power, in such a way that the power consumed by our agitators is the minimum necessary.

Our process engineering department will study the most appropriate impeller system for your process.