Our history

Our DNA, our team.

Xavier Torredeflot, Anna Torredeflot, Elisabet Rodriguez and Helena Rodríguez make up the management of Vak Kimsa, being the second generation of the family.

In figures

Founded in Barcelona

in 1972

100%

family property

2nd generation

made up of 4 siblings,

leading the company

We are 100%

national manufacturers

3,500 sqm

of installations

38 workers

29% university degree

+ of 21,000

equipment manufactured

+ 5% for R+D+i projects

CDTI projects

every 2 years

En - historia

Who we are

We’re your team. Human and technical ability to provide a global solution to your mixing processes since 1972

The passion and illusion in what we do moves us to provide you with the best solutions and the most technologically advanced agitators and mixers, optimized and flexible for the constant evolution of your products and processes.

We all have dreams and we want to share ours with you…

Technical Sales

We love to be attentive to your needs. Your project, our project.

“I love the world of motoring and traveling, sharing it with my family is my daily dream.”

Elisabet Rodriguez

Commercial Director

Head of Agitation Process - CEO

Engineer

“Practicing mountain biking and enjoying life with my family is the energy that moves me.”

Pere Jiménez

Head of Sales

EMMV ESADE

“If you want to be happy, start by loving what you do.” gsfdgsdfgsdfgsdfgsdfgsdfgsdfgsdfgsdfgdsfg

Joan Labró

Sales area manager

“Passionate about basketball, traveling, my family and friends.”

Ramon Codina

Sales Area Manager

Graduated in Business Management

“My dream is to share moments and experiences with my family and my friends.”

Raquel Malo

Assistant Commercial Technical Department

“Sport, nature and sharing moments with good people.”

María Morató

Departament Commercial - Process Engineering

Food Engineer

“I consider happiness a great paradoxy. That depends mostly in how we are. This is how I live my life.”

Lisseth Vilches

Assistant Commercial Department

We love to be attentive to your needs. Your project, our project.

“I love the world of motoring and traveling, sharing it with my family is my daily dream.”

Elisabet Rodriguez

Commercial Director

Agitation Process Manager – CEO

Engineer

“Practicing mountain biking and enjoying life with my family is the energy that moves me.”

Pere Jiménez

Sales manager

EMMV ESADE

“If you want to be happy, start by loving what you do.”

Joan Labró

Sales area manager

“The linear combination of sport, mountain and new challenges keep my energy alive.”

Conchi Espinar

Commercial Technical Department - Process Engineering

Chemistry

“The linear combination of sport, mountain and new challenges keep my energy alive.”

Ramon Codina

Sales Area Manager

Graduated in Business Management

“My dream is to share moments and experiences with my family and my friends.”

Raquel Malo

Assistant Technical Commercial Department

“Sport, nature and sharing moments with good people.”

Maria Morató

Commercial Technical Department-Process Engineering

Food Engineer

“Enjoying the little moments that life gives you.”

Elsa Muntada

Marketing Department

Publicity and PR student

Nos encanta estar pendientes de tus necesidades. Tu proyecto, nuestro proyecto.

“I love the world of motoring and traveling, sharing it with my family is my daily dream.”

Elisabet Rodriguez

Commercial Director

Head of Agitation Process – CEO

Engineer

“Practicing mountain biking and enjoying life with my family is the energy that moves me.”

Pere Jiménez

Head of sales

EMMV ESADE

“If you want to be happy, start by loving what you do.”

Joan Labró

Sales area manager

“My dream is to share moments and experiences with my family and my friends.”

Raquel Malo

Technical Sales Dept. Assistant

The advice, monitoring and management of tailor-made teams, as well as customer satisfaction are our objectives. We work as a team with process and product engineering to make our product selection the optimal solution for your mix.

Process Engineering

Generating the best ideas and solutions for your mixing processes

“I love traveling, living with other ways of understanding the world, remembering moments and landscapes.”

Helena Rodríguez

In line Mixers & Equipment Process Mgr. - R+D Mgr. - CEO

Physicist

“I love the world of motoring and traveling, sharing it with my family is my daily dream.”

Elisabet Rodriguez

Commercial Director

Head of Agitation Process – CEO

Engineer

“I enjoy looking at natural and human landscapes. If I can actively enhance them, I do it.”

Pere Pujol

Process technician

Industrial Engineer

“Practising sport, travelling and being with my loved ones is what gives me strenght and motivation on a daily basis.”

Oriol López

R+D

Mechanical Engineer

PhD Student

Generating the best ideas and solutions for your mixing processes

“I love traveling, living with other ways of understanding the world, remembering moments and landscapes.”

Helena Rodríguez

In line Mixers & Equipment Process Mgr. - R+D Mgr. - CEO

Physicist

“I love the world of motoring and traveling, sharing it with my family is my daily dream.”

Elisabet Rodriguez

Commercial Director

Agitation Process Manager – CEO

Engineer

“I enjoy looking at natural and human landscapes. If I can actively enhance them, I do it. “

Pere Pujol

Process technician

Industrial Engineer

“Practising sport, travelling and being with my loved ones is what gives me strenght and motivation on a daily basis.”

Oriol López

R+D

Mechanical Engineer

PHd Student

Generating the best ideas and solutions for your mixing processes

“I love traveling, living with other ways of understanding the world, remembering moments and landscapes.”

Helena Rodríguez

Process Engineering Director – CEO

Physicist

“I love the world of motoring and traveling, sharing it with my family is my daily dream.”

qwertyuiop

Elisabet Rodriguez

Commercial Director

Agitation Process Manager – CEO

Engineer

“I enjoy looking at natural and human landscapes. If I can actively enhance them, I do it. “

qwertyuiop

Pere Pujol

Process technician

Industrial Engineer

“Practising sport, travelling and being with my loved ones is what gives me strenght and motivation on a daily basis. “

qwertyuiop

Oriol López

R+D

Mechanical Engineer

PHd Student

The selection, design and execution of our range of agitators, in-line mixers and complete mixing equipment, requires high competence in process engineering and applications to provide optimal solutions that go far beyond the mere knowledge of the equipment itself.

We intervene in your project from the beginning to the end, always starting from the specific needs and as far as you want us to accompany you.

EN - ING PROCESO

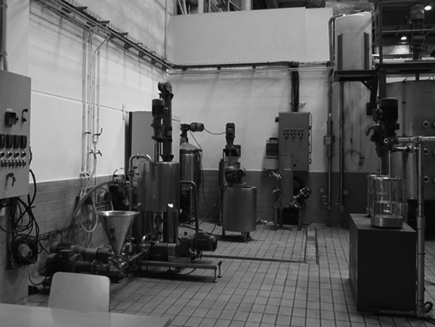

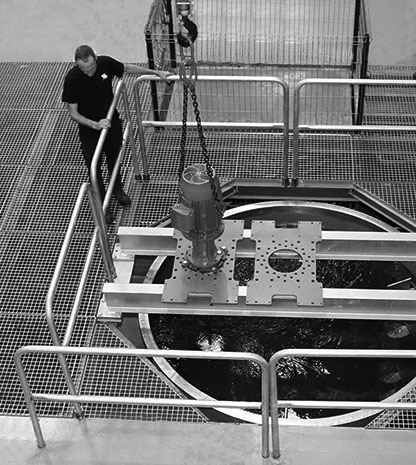

PILOT PLANT: possibility of carrying out process tests in our pilot plant

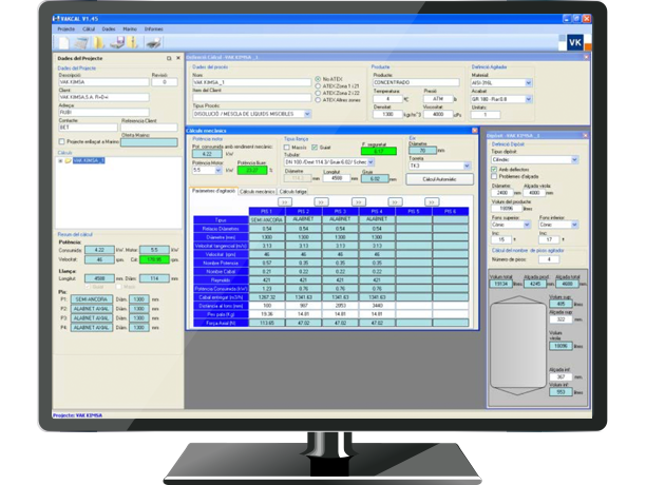

VAKCAL: our agitator calculation program

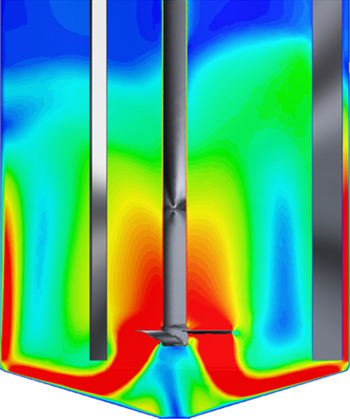

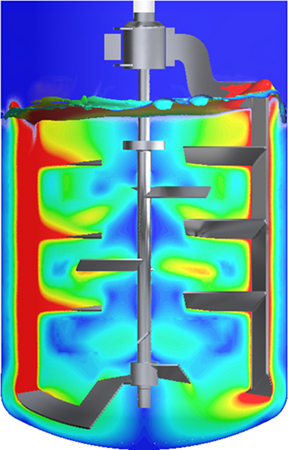

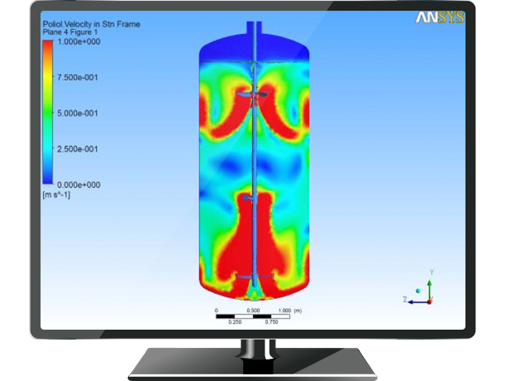

ANSYS: fluid dynamic process simulations ANSYS-CFX

The passion to know more. Constant research and innovation at your fingertips.

From a continuously validated and acquired Know How from the R+D+i department we contribute to the development of the best possible solutions to the changing needs of our customers and markets.

This quest for excellence is carried out around three axes:

1. Research

We investigate complex mixing processes and dynamic phenomena typical of rotary machines. Some examples are: maintenance in suspension of solid particles, agitation of highly non-Newtonian products and predictive maintenance. Some of these lines of research are endorsed by entities recognized as the CDTI (Center for Technical and Industrial Development).

Liquid-solid multiphase simulation (TRIVAK impeller). A – Velocity contour in the vertical plane of the tank. B – Volumetric fraction of the solid phase. Partially suspended.

2. Development

We contribute to the optimization of the equipment, both from the process point of view and from the product point of view (minimization of dead zones, reduction of weight of the equipment, minimization of consumption, etc.).

3. Innovation

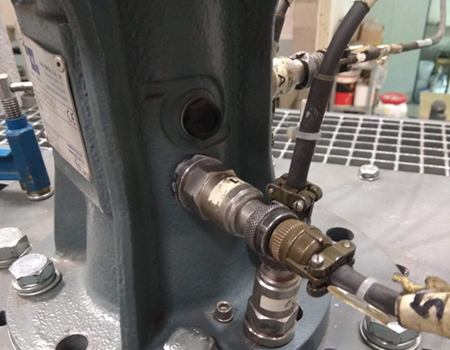

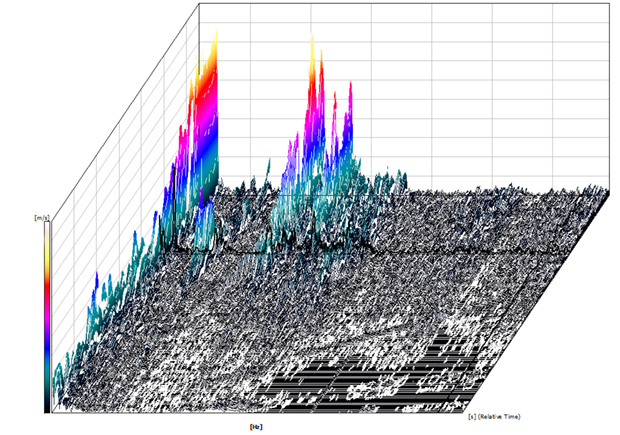

We work to offer solutions that allow us to give a faster response to our customers (development of calculation software and sizing of agitators called VAKCAL) and ensure the quality and reliability of our equipment (minimize operation and maintenance costs based on data of dynamic behavior of the machine in the framework of Industry 4.0).

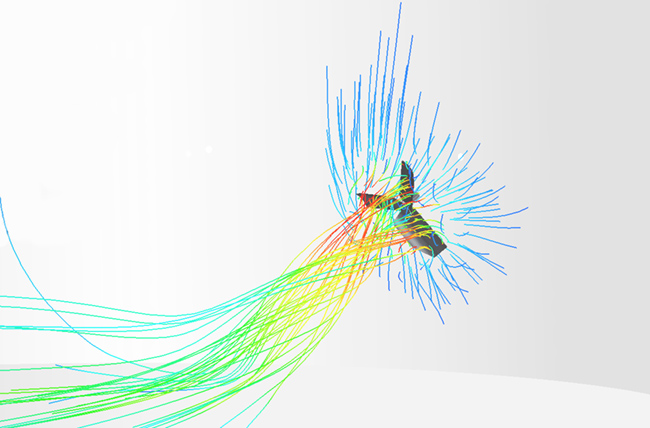

We achieve these three axes by means of internationally recognized numerical simulation tools (ANSYS CFD and Mechanical software) and a pilot plant equipped with sensors and first-rate data acquisition equipment, which we use internally, as well as making them available to our customers for joint collaboration.

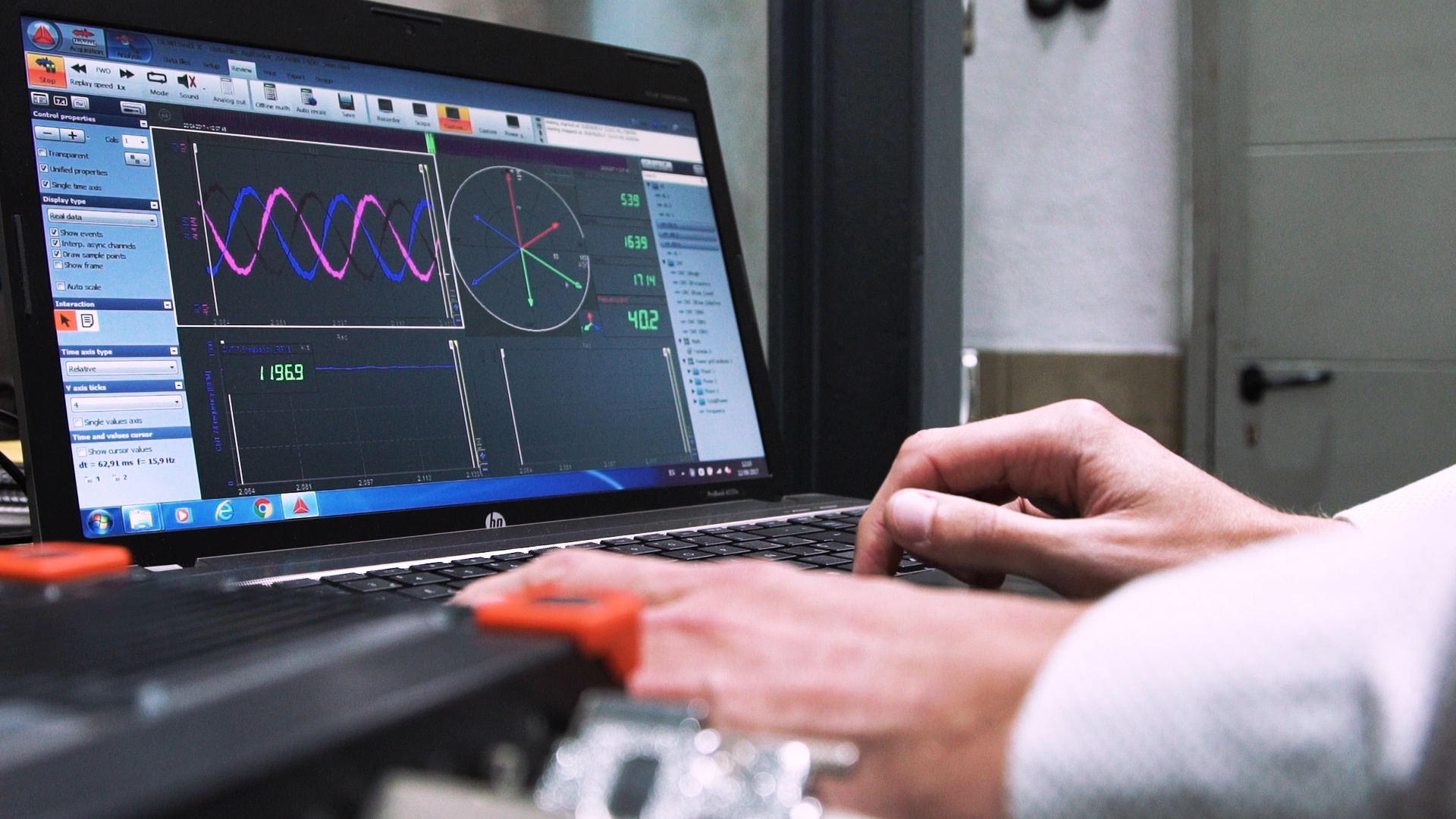

Flow lines of a lateral agitator with ANSYS (TRIVAK impeller)

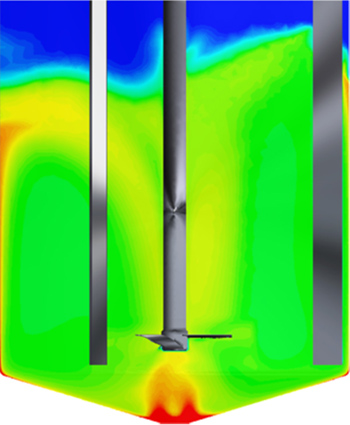

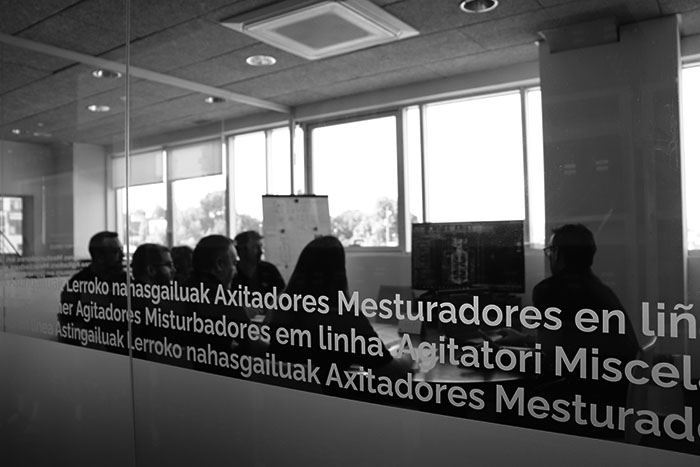

Pilot plant. Experimental measures.

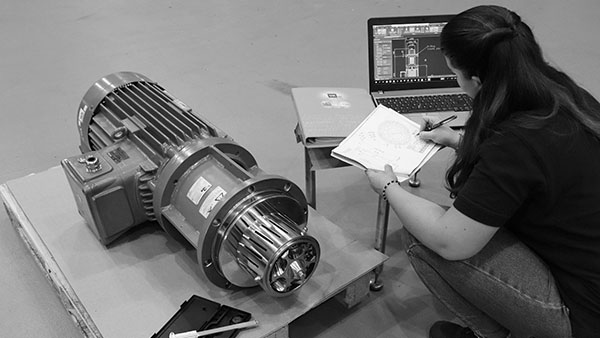

Product Engineering

Excited to design and manufacture the best agitators and mixers for you

“My dream is to sail and get lost in the oceans, being able to enter the atolls with my JUGUESCA (my boat).”

Xavi Torredeflot

Industrial Director – CEO

“I am passionate about traveling and learning about new cultures, walking and listening to good music.”

Ana María Cuesta

Purchasing and Logistics Department

“Go around the world by bicycle.” fasdfasdfasdfasdfasdfasdfasdfasdfasdf asdfasasdf

Oriol Escoda

Production Director

“Forming a family and being able to travel the world with it is what gives me strength every day.”

Sergio Gómez

TAS manager

“I love travelling” fasdfasdfasdfasdfasdfasdfasdfasdfasdf asdfasasdf

Carlos Fraile

Quality Manager

“I love riding a motorcycle and the freedom that it makes me feel. I like the smell of wet earth when the first drops of rain fall.”

Toni Mena

Technical Office

“Forming a family and being able to travel the world with it is what gives me strength every day.”

David Calvente

Department of Purchasing and Logistics

“Travel the world by train” QQQQQQQQQQQQQQQQQQQQQQQQQQW

Nacho Moreno

Technical Office

Mechanical Engineer

“I am passionate about motorcycling, mechanics and travelinb by van.”

Joan Fernández

Technical Office

“Transparency, curiosity, energy and creativity as a life path.”

Berta Miró

Technical Office

Industrial design engineer and product development

Excited to design and manufacture the best agitators and mixers for you

“My dream is to sail and get lost in the oceans, being able to enter the atolls with my JUGUESCA (my boat).”

Xavi Torredeflot

Industrial Director – CEO

“I am passionate about traveling and learning about new cultures, walking and listening to good music.”

Ana María Cuesta

Purchasing and Logistics Department

“Go around the world by bicycle.”

Oriol Escoda

Production Director

“Forming a family and being able to travel the world with it is what gives me strength every day.”

Sergio Gómez

TAS manager

“I love travelling”

Carlos Fraile

Quality Manager

“I love riding a motorcycle and the freedom that it makes me feel. I like the smell of wet earth when the first drops of rain fall. “

Toni Mena

Technical Office

“Forming a family and being able to travel the world with it is what gives me strength every day.”

David Calvente

Department of Purchasing and Logistics

“Travel the world by train”

Nacho Moreno

Technical Office

Mechanical Engineer

“Travel the world by train”

Joan Fernández

Technical Office

Reliability in design and manufacture

- 2D design with Autocad 2019 and 3D design with INVENTOR.

- Mechanical calculations with VAKCAL’s own program.

- Simulation: Possibility of carrying out ANSYS-MECH mechanical simulations.

- Traceability with ERP and plant data capture.

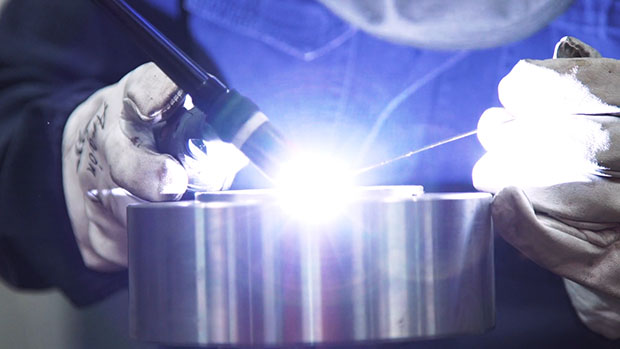

Manufacturing

We keep the secret of a production with care, the details are important

We keep the secret of a production with care, the details are important.

A modern infrastructure and a qualified human team

- ERP integrated management system, with MRP needs calculation.

- Own machining workshop: numerical control parallel lathes, 6 m long parallel lathe, numerical control milling cutter, TIG welding, plasma cutting, …

- Notching machine.

- Laser cutting.

- Own assembly workshop.

- Raw materials from approved suppliers with guaranteed traceability.

- 100% quality control of the manufactured equipment.

- Traceability.

In Quality, we leave nothing to chance

Our primary objective is to meet 100% of our customers’ expectations.

Static quality control:

Verification of 100% of agitators and mixers before shipment, following our quality protocols.

Dynamic quality control:

We dynamically test agitators and in-line mixers. We have test tanks up to 25 m3, as well as a test bench for in-line mixers.

At SAT we are always attentive to details

We advise you so that you can carry out the installation, assembly and commissioning yourselves.

We can offer you the service of assembly and commissioning assembly and commissioning by our expert assemblers.

We have maintenance manuals and spare parts supply service.

And always ready for after-sales service.

Administration and finance

From excellence, we provide solutions and services to our organization, since we are the gear that connects the VAK KIMSA team.

“Happiness is doing what you love and lovingwhat you do, this is the maxim that inspires my dreams and my life.” dsfgsdfgdsfgsdfgsdfgsdfgsdfgdsfgsdfgsdfgsdfg

Anna Torredeflot

Finance and HR Director – CEO

Economic Sciences

“Surrounding myself with good people, learning about new cultures and traveling the world, doing what makes me happy at all times.”

Meritxell Ruana

Financial Department - Customer area

Business Management

From excellence, we provide solutions and services to our organization, since we are the gear that connects the VAK KIMSA team.

“Happiness is doing what you love and lovingwhat you do, this is the maxim that inspires my dreams and my life.”

Anna Torredeflot

Finance and HR Director – CEO

Economic Sciences

“Surrounding myself with good people, learning about new cultures and traveling the world, doing what makes me happy at all times.”

Meritxell Ruana

Financial Department - Customer area

Business Management