Pilot plant

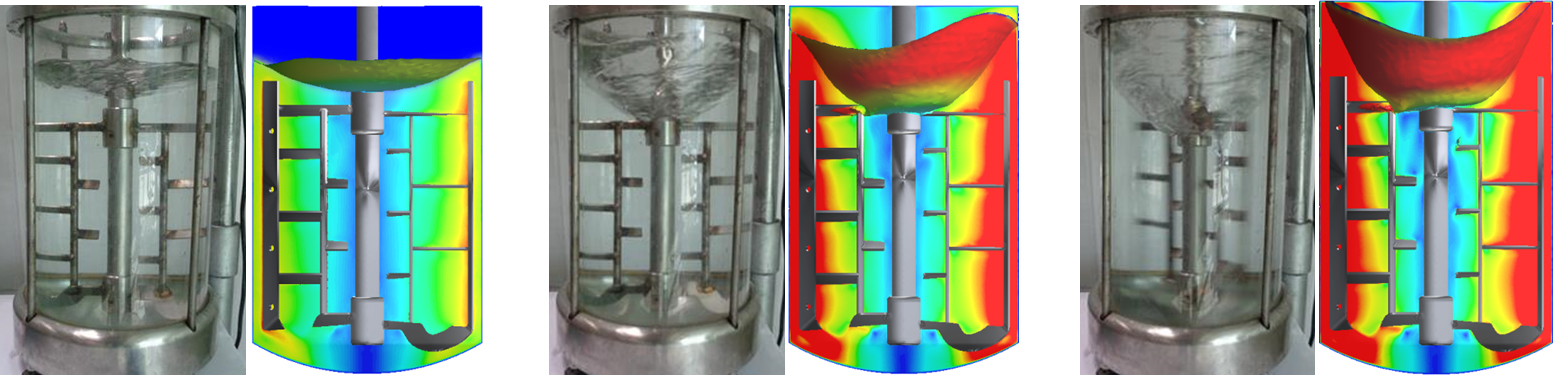

Vak Kimsa offers the possibility of carrying out experimental tests with your product in our facilities. This allows you to get to know first-hand how your product will behave in our equipment and the advantages they offer.

For this purpose, VAK KIMSA has different in-line agitation and mixing equipment that allows empirically validating a wide range of processes and all types of products. We have tanks of 15l, 50l, 80l, 150l, 1500l and 25.000l, as well as in-line mixing equipment for batch production. These tests allow the results to be extrapolated to ensure effective and efficient industrial scaling of equipment.

In addition, the pilot plant is equipped with a viscometer and data acquisition equipment that allows the rheology of the products and certain operating parameters of the agitators to be obtained. This makes it possible not only to analyse and optimise the behaviour of the agitator from the fluid dynamic point of view, but also from the mechanical point of view (stresses and dimensioning) and its energy consumption.

“These facilities allow VAK KIMSA to consolidate our KNOW-HOW, which translates into optimized products and adapted to each of the needs of our customers”

Industrial scale platform

We have an industrial scale platform with tanks of 1,500 and 25,000 liters to carry out the pre-delivery quality tests of the agitators and in-line mixers manufactured, being able to verify them at the process level and at the mechanical level.

Likewise, our R+D+i department works on the development of our product with the platform on an industrial scale.

ANSYS fluid-dynamic simulations

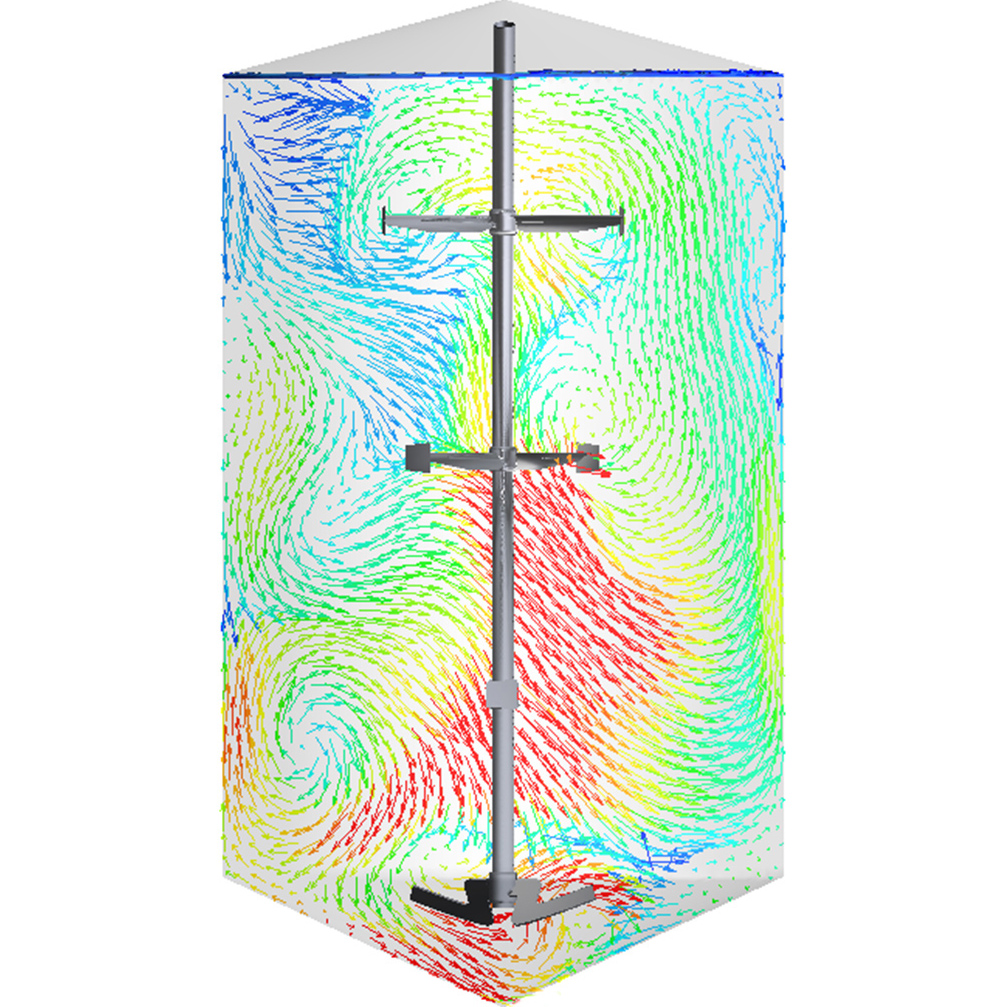

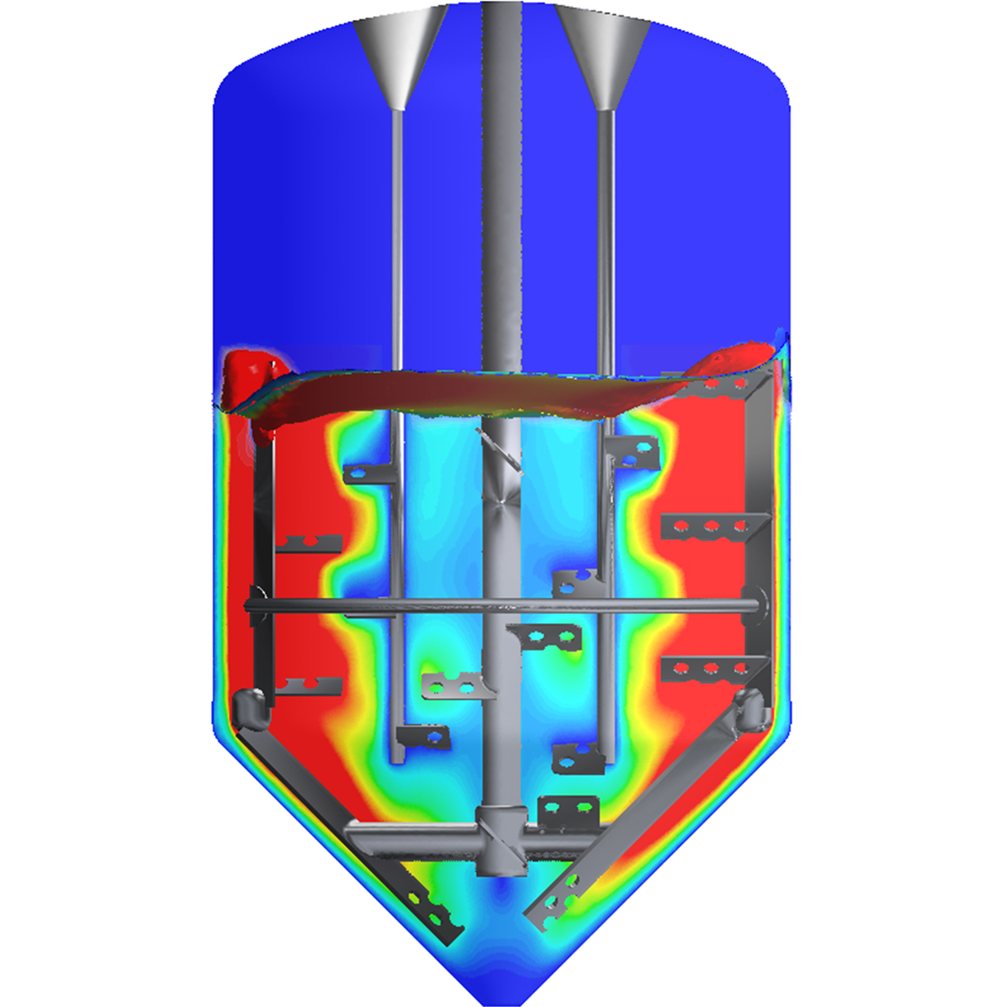

Fluid-dynamic simulations make it possible to see how the fluid behaves inside the tank depending of the agitator and established operating parameters.

This tool provides the flow patterns from which it is possible to optimize the process, in order to provide the best possible solution to meet each particular need of our customers.

Establishing the need or not for baffles, knowing the behavior of non-Newtonian fluids, preventing the presence of dead zones, determining the power consumed, defining the average speed of the fluid, etc. are frequent questions that can be resolved using this type of analysis.

VAK KIMSA has extensive knowledge in the use of simulation tools such as ANSYS, which together with the validated Know-How in mixing processes and the possibility of carrying out tests in a pilot plant, allow us to offer the best solutions to the continuous and growing production challenges faced by our customers.

Vakcal

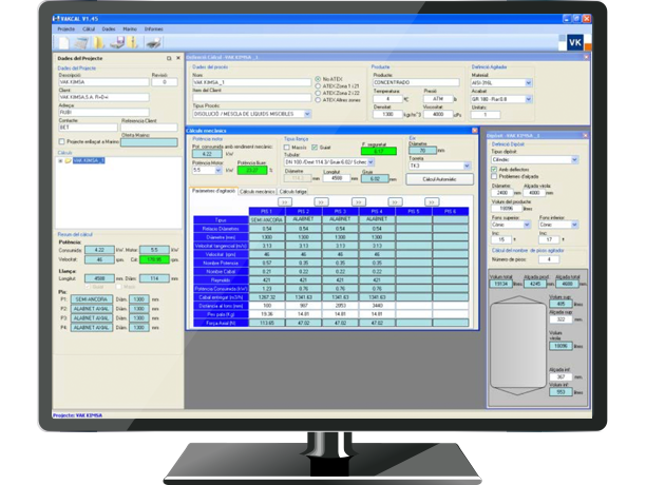

VAKCAL, agitator calculation program

Vak Kimsa has a specific program for the design of agitators called VAKCAL. This software, of own development, allows us to dimension customized agitation equipment for each product-process of our clients.

This program is equipped with an extensive database at process level that allows to determine, automatically, the optimal agitator required to carry out a specific process, both from the technical and economic point of view.

In addition, this software is connected to the CRM and ERP management system, so there is full traceability about each and every agitator that is quoted.

Adaptation of projects

Following the marketing department, advice on readaptation of agitators and mixing equipment to new products.

1) When Marketing proposes the creation of new products and production has to follow at dizzying rates, it raises the need to choose the right equipment to manufacture the new product, we help you in the choice, you know your product, and we know about agitators and mixing equipment.

2) When the factory does not have the right mixing equipment for the new product it is necessary to seek solutions urgently; a readaptation of the agitator or a new one. We help you follow the pace you need with the right agitator, in the time you need.

Training courses on mixing technology

We like to share our KNOW HOW!

At Vak Kimsa it is very important that our customers are up to date with mixing technology, so we teach technical courses in Agitation and In-line Mixing Technology.

Complete training courses on AGITATION AND IN-LINE MIXING TECHNOLOGY,

Online Webinars

30-45′ monographic courses on mixing technology, where case studies are shared online.

30-45′ monographic courses on mechanical concepts of agitators and in-line mixers, to ensure correct installation, start-up and operation.