At VAK KIMSA we have the human and technical capacity to provide a global solution to your mixing processes.

Our mastery of agitation technologies and in line mixing gives us a global perspective on the conception and implementation of mixing processes. With the combined use of both technologies we offer complete mixing equipments, which reduce productions times, optimize excellent end-product-quality.

Batch and continuous manufacturing.

- Mixing by agitation and in-line mixing.

- Dosing of raw materials.

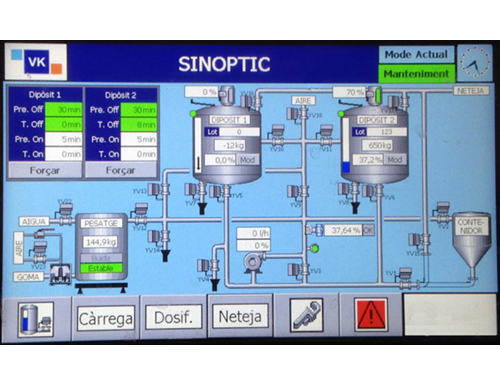

- Process control and automation.

- Reduction of manufacturing times.

Optimization of the installed power.

- Obtaining excellence in the manufactured product.

Complete mixing equipments for the homogenization of powdered solids with ALVAK mixer. Food, cosmetics and chemical industry.

Complete mixing equipments for homogeneous mixing of thickening and texturizing solids, with VISCOVAK mixer and agitator for efficient heat exchange. Food, cosmetics and chemical industries.

Production in batches

Optimization in batch manufacturing

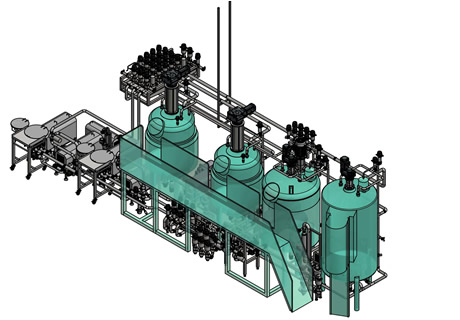

Agitation and in line mixing technologies are combined and strengthened, producing complete facilities for batch manufacturing products. The agitators and in line mixers used, automated dosing of components, process monitoring… ensure optimum results for our complete batch facilities.

Complete VISCOVAK plants for the production of mayonnaises and other emulsified and chunky sauces. Emulsion, pasteurization, cooling, deaeration. Automatic installation. Food industry.

3D Plant

Advantages

- Great flexibility in production.

Very useful when there is a large variaton of recipes.

High production volume with in-line mixers.

Complete mixing plant for dispersion, dissolution and emulsion. Heating and vacuum. Food, cosmetics and chemical industries.

Transportable manual Atex mixing plant, with flameproof cabinet.

Characteristics

- Processes: mixing, emulsion, dilution, dissolution and dispersion.

- Dosage of majority and minority liquids.

- Dosing of solids.

- Automation and recipe management.

Process control.

Agitators for the homogenization, thermal exchange and deaeration of high viscosity sauces. Homogeneous maintenance of solids.

Deposits of maintenance, waiting, packaging.

Manufacture of solids solutions in liquids with Turbvak agitator.

Recommended equipment:

Complete installations for mixing solids and minority liquids in the manufacture of creams and sauces. Food industry.

Maintenance of solid suspensions and dosage to formulation. Chemical industry.

Complete installation of a mixture of titanium dioxide, carbonates and general charges, with resins and other liquids, in the manufacture of paints, varnishes and inks. Chemical industry.

Preparation of minority ingredient solutions. Chemical and cosmetics industry.

Continuous manufacturing

Standard and homogeneous final product

In-line mixing technology, together with experience in liquid dosing and continuous monitoring, guarantee the continuous production of a completely standardized and homogeneous final product.

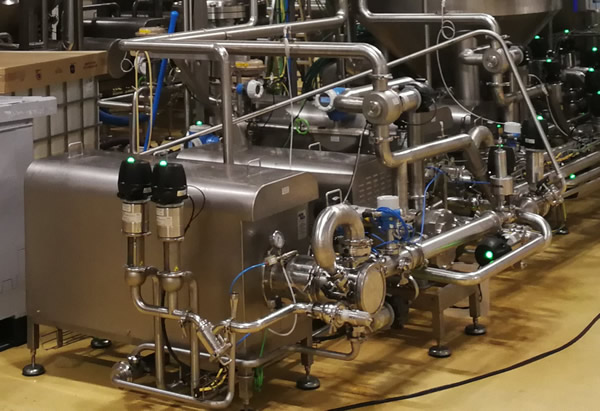

Continuous mixing plant with LIVAK mixer and liquid dosing. Chemical and cosmetics industry.

Continuous dilution of concentrated liquid received in tanker truck. The product solidifies in cold, the mixture is guaranteed with the LIVAK mixer, the continuous dosage of liquids is carried out by instantaneous flow measurement. Chemical and cosmetics industry.

Continuous mixing plant with LIVAK mixer and liquid dosing. Chemical and cosmetics industry.

Continuous dilution of concentrated liquid received in tanker truck. The product solidifies in cold, the mixture is guaranteed with the LIVAK mixer, the continuous dosage of liquids is carried out by instantaneous flow measurement. Chemical and cosmetics industry.

Application

Manufacture of sauces, mixing of chocolate and fats, dissolution of sugar, mixture of oils, mixture of juices or concentrates, dilution of concentrated products, post-addition of minorities, dilution of sodium lauryl ether sulphate, correction of pH, neutralization, manufacture of cosmetic creams, liquid soaps, liquid detergents, household cleaners, fabric softeners…

Advantages

- Just in time production.

- High production volume with little occupation of space.

Characteristics

- Processes: mixing, emulsion, dilution and dissolution.

- Continuous dosing of majority and minority liquids.

- Continuous dosage of solids.

- Automation and recipe management.

- Process control.

Complete installation of continuous mixing of liquids, LIVAK mixer, dosing by flow. Chemical industry.

Continuous production of food and cosmetic emulsions. Food and cosmetics industry.

Complete installation of continuous mixing of liquids, LIVAK mixer, dosing by flow. Chemical industry.

Continuous production of food and cosmetic emulsions. Food and cosmetics industry.

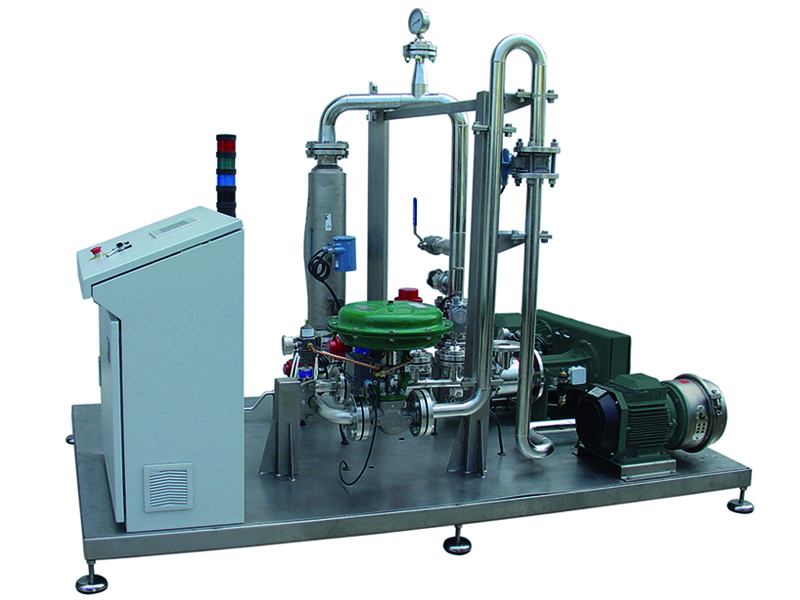

SLES dilution: LAURILVAK

Dilute concentrate in your plant and save on transport

In-line mixing equipment for the dilution of SLES (sodium lauryl ether sulphate) from 70 to 27%; dosing of raw materials and continuous mixing. The concentrate can come directly from a tanker truck, so it is diluted (22 Tm of LESS 70 in 1h 30min) at the same time as the diluted product is unloaded and stored. The concentrate can also be stored and diluted according to production requirements.

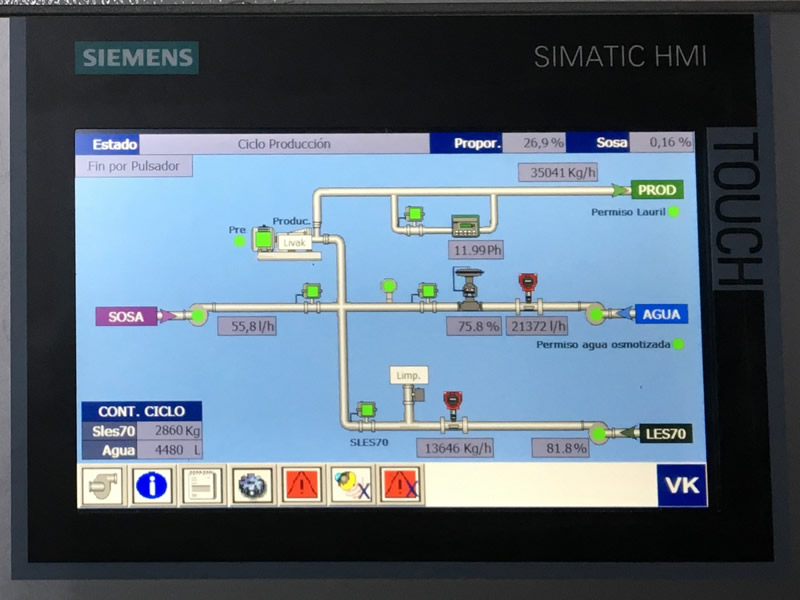

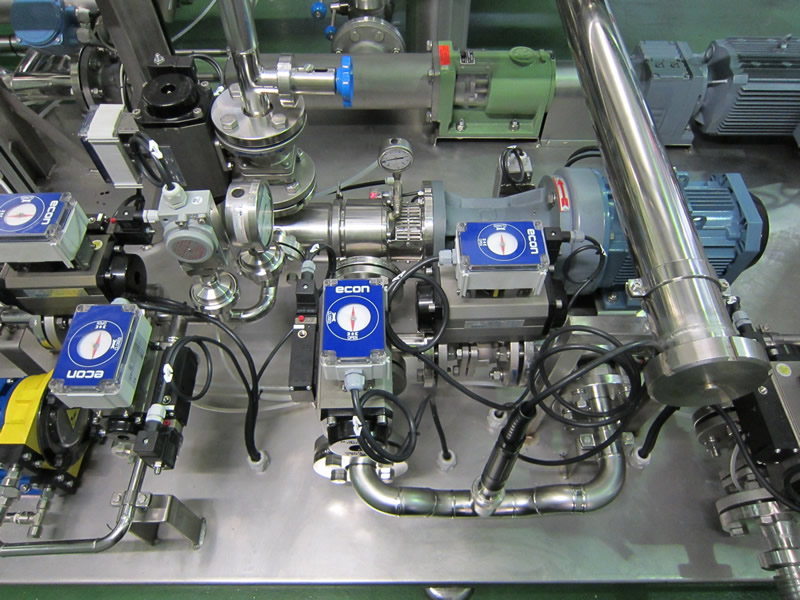

The equipment consists of continuous dosing of 70% LESS, water and preservative, followed by continuous mixing carried out by a LIVAK in-line mixer. A PLC takes care of the process control and its automatic operation.

The concentrate can come directly from a tanker truck, so it is diluted at the same time as the diluted product is unloaded and stored. The concentrate can also be stored and diluted according to production requirements.

LAURILVAK

Operator console and process visualization. Laurilvak

Continuous pH regulation. Laurilvak.

Unloading and direct dilution of tanker truck in 1h 30min. Laurilvak. Detergency industry.

Characteristics

- Dilution of sodium lauryl ether sulphate from 70 to 27%.

- Final product selectable between 20 and 27%.

- Production of SLES 27 from 10 to 40 m3/h.

- Unloading and direct dilution of tanker truck in 1 h 30 min.

- Continuous pH regulation (optional).

Advantages

- Savings in transport and purchase price of raw material.

| Type | Production LESS 27% (l/h) | Total power (kW) | Dilution truck 22 Tm (h) |

| LAURILVAK 1 | 10.000 | 12 | — |

| LAURILVAK 3 | 40.000 | 32 | 1,50 |

Laurilvak installed in the tank truck unloading area. Unloading and direct dilution of tanker truck. Cosmetic industry.

Laurilvak which dilutes lauryl ether sodium sulphate stored in tank. Detergency industry.