Guarantee for reliable and long-lasting mechanics

At VAK KIMSA we give great importance to the bearing box, since it guarantees the mechanical reliability and durability of the agitator.

In the bearing box there is:

- Bearings.

- Sealing.

- Stainless steel lining.

| RANGE | TD | HT | TK | TK-TC | |

| Sizes | TD0 | HT0 HT1 HT2 HT3 HT4 HT5 |

TK0 TK1 TK2 TK3 TK4 TK5 TK6 |

TK0-TC1 TK1-TC2 TK2-TC3 TK3-TC4 TK4-TC5 TK5-TC6 TK6-TC7 |

|

| Power (kW) | 0,18 ÷ 0,75 | 0,37 ÷ 45 | 0,37 ÷ 110 | 0,37 ÷ 110 | |

| Sealing | Lip-seal | X | X | X | X |

| Stuffing box | X | X | |||

| Mechanical seal | X | X | |||

| ATEX version | X | X | X | X | |

| Aseptic Version | X | X | |||

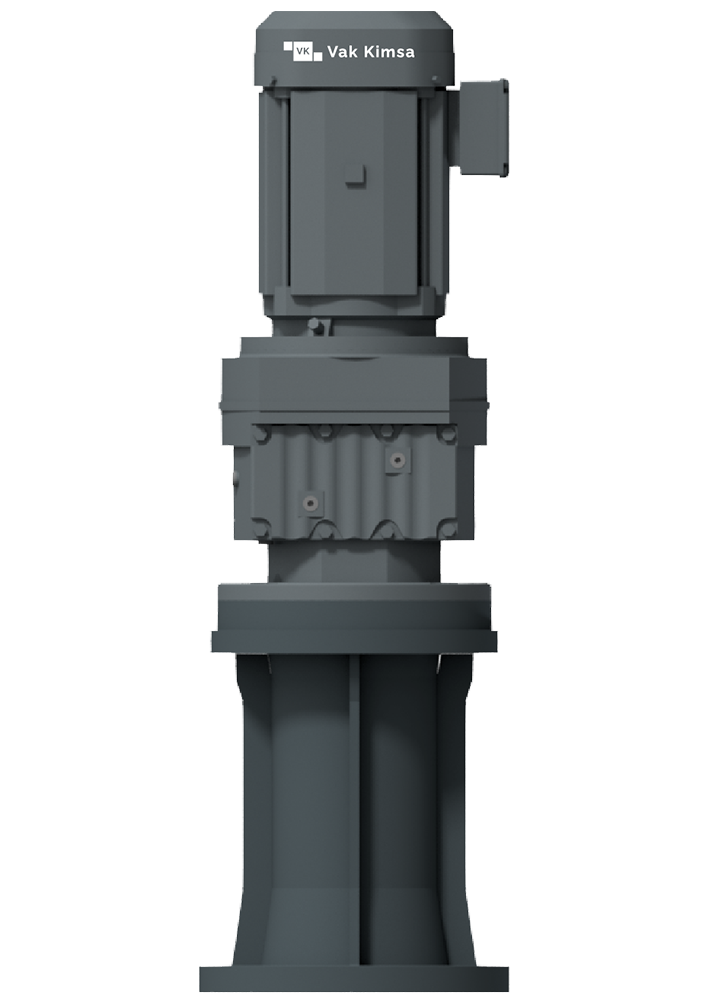

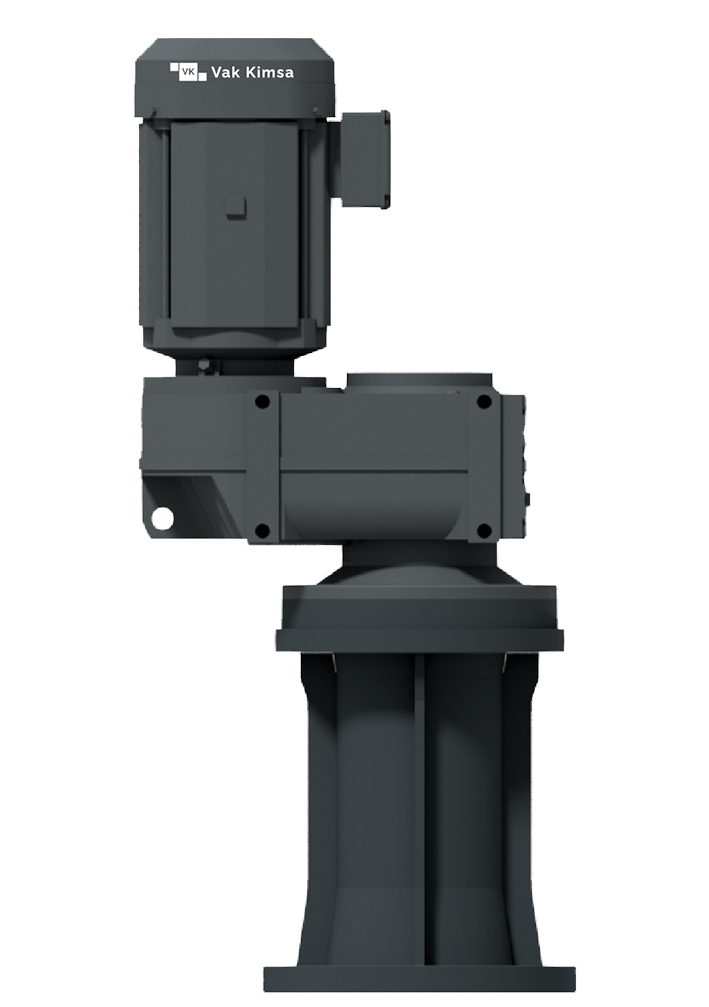

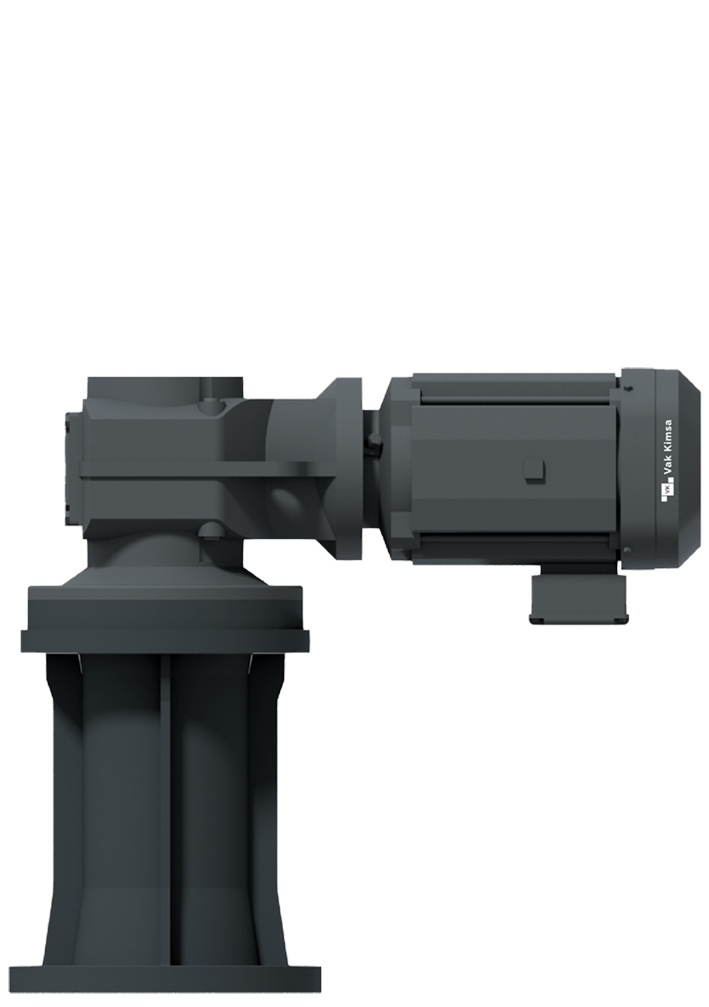

Drivings

TD0 BEARING BOX

0,18 ÷ 0,75 kW.

- Suitable for volumes up to 1000 liters.

- For low viscosity products.

- Standard impeller type TRILIGHT.

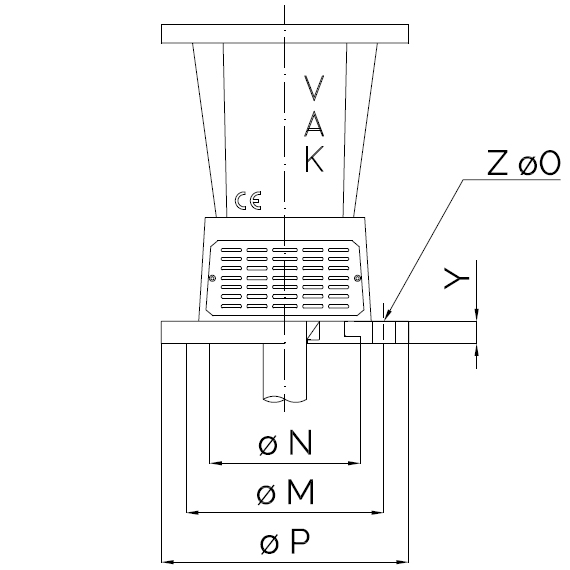

HT BEARING BOX

0,37 ÷ 45 kW.

- They are used in atmospheric conditions of pressure, vacuum and/or temperature.

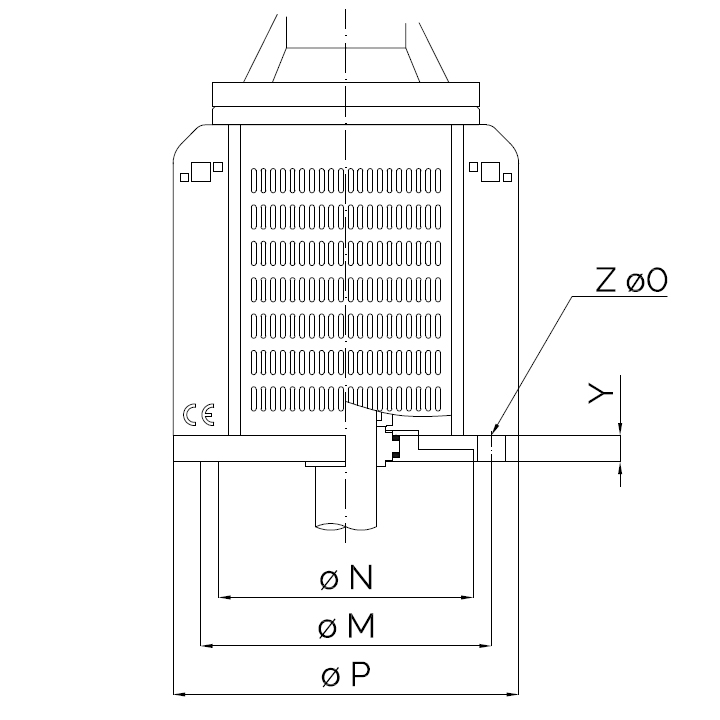

| HT BEARING BOX LANGES | |||||||||

| BEARING BOX | ØP | ØM | ØN | Z | Ø0 | DIN – 2576 | ØT | Y | |

| máx. | mín. | ||||||||

| HT0 | 200 | 160 | 122 | 4 | 18 | DN80 PN10 | 110 | 80 | 18 |

| BEARING BOX | ØP | ØM | ØN | Z | Ø0 | DIN – 2501 | ØT | Y | |

| máx. | mín. | ||||||||

| HT1 | 250 | 210 | 180 | 8 | 18 | DN125 PN10 | 170 | 125 | 20 |

| HT2 | 340 | 295 | 266 | 8 | 22 | DN200 PN0 | 250 | 200 | 30 |

| HT3 | 395 | 350 | 320 | 12 | 22 | DN250 PN10 | 300 | 250 | 26 |

| HT4 | 445 | 400 | 370 | 12 | 22 | DN300 PN10 | 350 | 240 | 30 |

| HT5 | 565 | 515 | 440 | 16 | 27 | DN400 PN10 | 420 | 300 | 36 |

* Dimensions in mm. Z = number of holes. ØN = Ø lining in stainless steel. The lining guarantees that the area in contact with the product is in stainless steel.

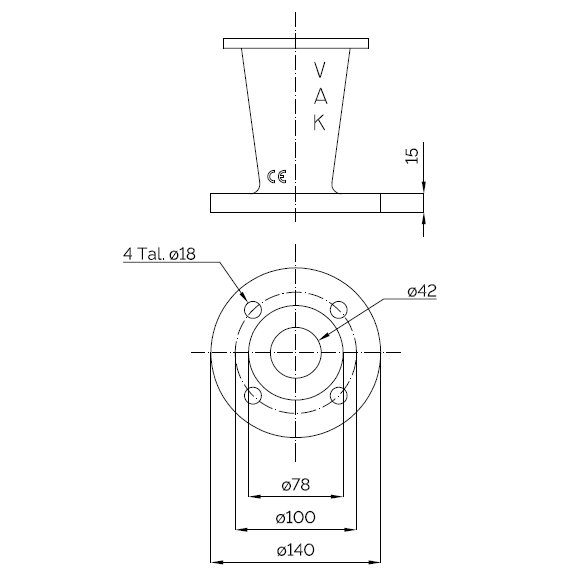

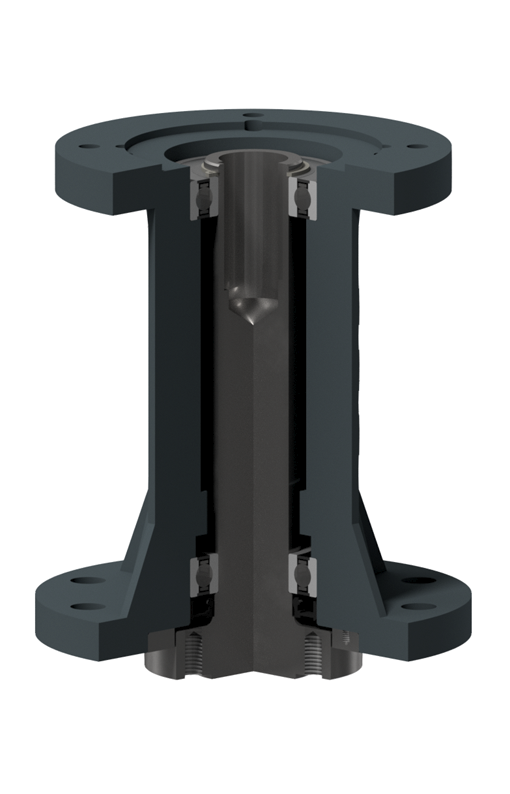

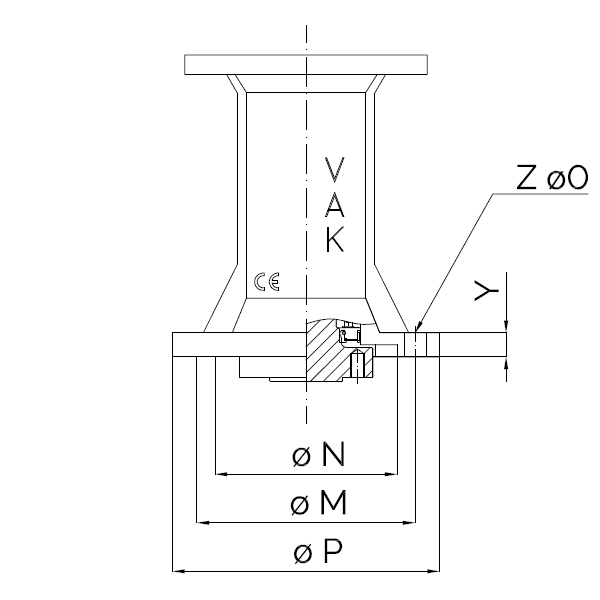

TK BEARING BOX

0,37 ÷ 250 kW.

- They are used in atmospheric conditions of pressure, vacuum and/or temperature.

| TK BEARING BOX FLANGES | |||||||||||

| BEARING BOX | ØP | ØM | ØN | Z | Ø0 | S/DIN – 2501 | ØT | ØT SISTEMA ALIMENTARIO |

Y | ||

| máx. | mín. | ||||||||||

| TK0 | 220 | 180 | 150 | 8 | 18 | DN100 PN10 | 140 | 115 | 140 | +0,2 | 25 |

| +0,3 | |||||||||||

| TK1 | 285 | 240 | 210 | 8 | 23 | DN150 PN10 | 190 | 138 | 165 | +0,2 | 25 |

| +0,3 | |||||||||||

| TK2 | 340 | 295 | 266 | 8 | 23 | DN200 PN10 | 250 | 165 | 202 | +0,2 | 35 |

| +0,3 | |||||||||||

| TK3 | 395 | 350 | 320 | 12 | 23 | DN250 PN10 | 300 | 240 | 240 | +0,2 | 40 |

| +0,3 | |||||||||||

| TK4 | 445 | 400 | 370 | 12 | 23 | DN300 PN10 | 355 | 300 | X | 28 | |

| TK5 | 565 | 515 | 475 | 16 | 27 | DN400 PN10 | 460 | 350 | X | 32 | |

| TK6 | 670 | 620 | 525 | 20 | 27 | DN500 PN10 | 515 | 495 | X | 38 | |

* Consult the technical office of Vak Kimsa, S.A.

** Dimensions in mm. Z = number of holes. ØN = Ø lining in stainless steel. The lining guarantees that the area in contact with the product is in stainless steel.

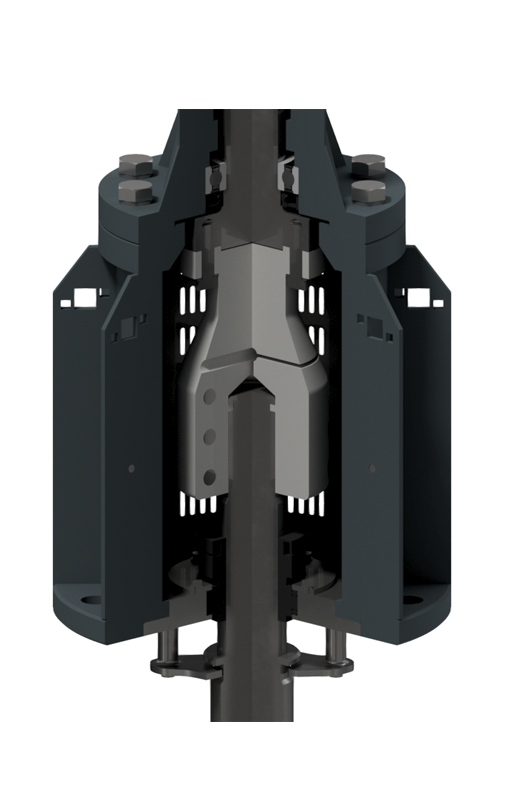

TK-TC BEARING BOX

0,37 ÷ 250 kW.

- For mechanical seal assembly, the TK turrets are complemented by the TC lower turrets.

| TK-TC BEARING BOX FLANGES | |||||||||

| BEARING BOX | ØP | ØM | ØN | Z | Ø0 | S/DIN – 2501 | ØT | Y | |

| máx. | mín. | ||||||||

| TK0/TC1 | 285 | 240 | 210 | 8 | 23 | DN150 PN10 | 200 | 150 | X |

| TK1/TC2 | 340 | 295 | 266 | 8 | 23 | DN200 PN10 | 240 | 200 | X |

| TK2/TC3 | 395 | 350 | 320 | 12 | 23 | DN250 PN10 | 300 | 250 | X |

| TK3/TC4 | 445 | 400 | 370 | 12 | 23 | DN300 PN10 | 350 | 300 | X |

| TK4/TC5 | 565 | 515 | 475 | 16 | 27 | DN400 PN10 | 460 | 300 | X |

| TK5/TC6 | 670 | 620 | 525 | 20 | 27 | DN500 PN10 | 515 | 350 | X |

| TK6/TC7 | 780 | 725 | 675 | 20 | 30 | DN600 PN10 | 650 | X | X |

* Consult the technical office of Vak Kimsa, S.A.

** Dimensions in mm. Z = number of holes. ØN = Ø lining in stainless steel. The lining guarantees that the area in contact with the product is in stainless steel.