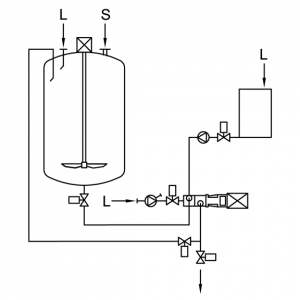

In-line liquid-liquid and solid-liquid mixer with addition of solid to the tank

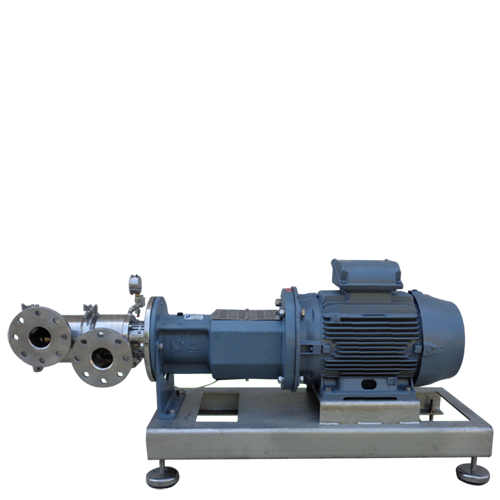

LIVAK in-line mixer with industrial finish, it has a pressurization and lubrication circuit for the mechanical seal. ATEX certified equipment according to Directive 2014/34/EU, for use in potentially explosive atmospheres. Chemical industry.

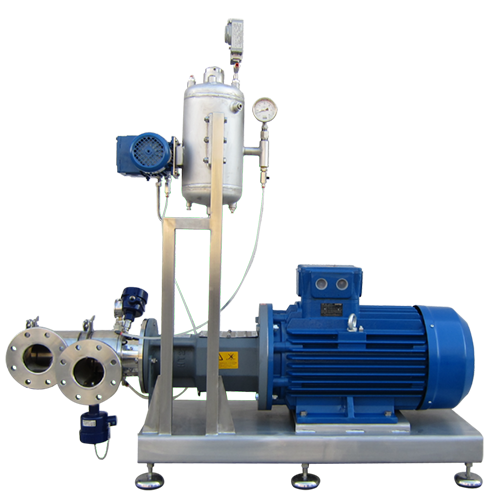

LIVAK in-line mixer with sanitary finish, it has a pressurization and lubrication circuit for the mechanical seal, as well as an electrical cabinet. Cosmetic industry.

LIVAK in-line mixer designed according to EHEDG and installed in recirculation on tank. Biotechnology industry.

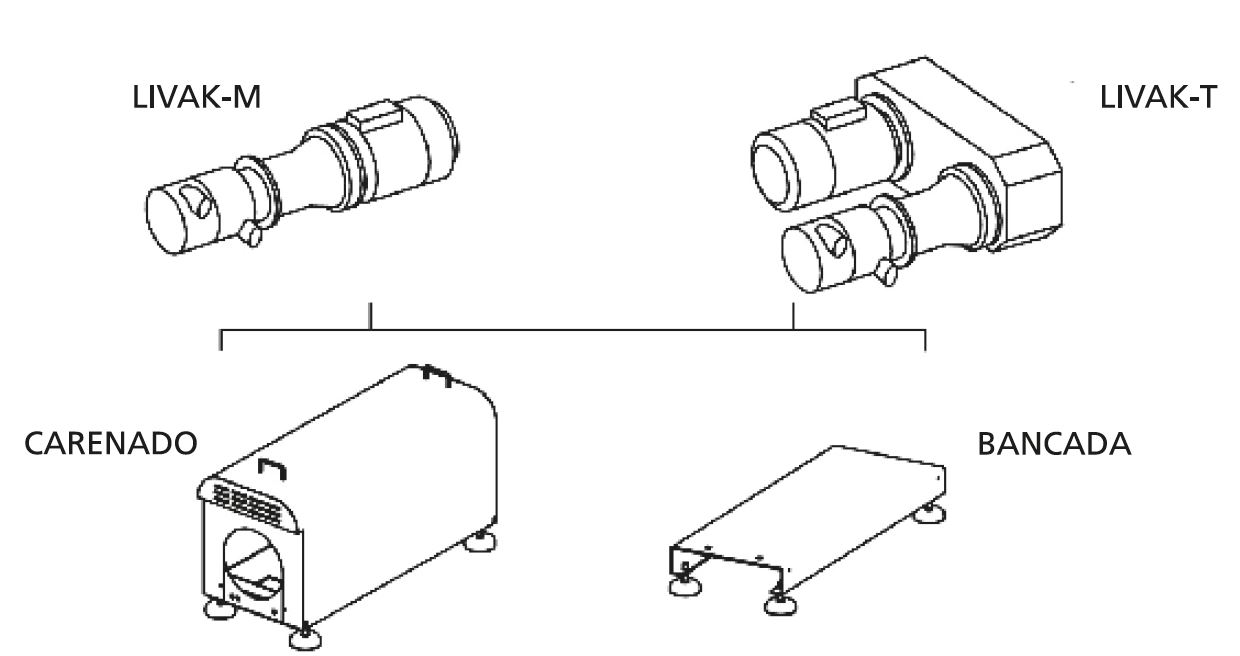

COMPONENTS

Liquids + liquids. Powdered, crystalline or granulated solids + liquids

SOLIDS CONCENTRATION

≤ 80%, depending on product

PRODUCT VISCOSITY

High-Medium-Low

MIXING FLOW RATE

≤ 90,000 l/h

Technical characteristics

| Types | LIVAK Power (kW) |

Liquid connection (DN) |

Maximum mixing flow (l/h) |

| LIVAK 00 | 0,55 ÷ 1,5 | 15 ÷ 25 | 500 |

| LIVAK 01 | 2,2 ÷ 5,5 | 25 ÷ 40 | 10.000 |

| LIVAK 1 | 4 ÷ 15 | 40 ÷ 65 | 25.000 |

| LIVAK 2 | 7,5 ÷ 22 | 65 ÷ 80 | 40.000 |

| LIVAK 3 | 15 ÷ 37 | 65 ÷ 100 | 60.000 |

| LIVAK 4 | 22 ÷ 55 | 80 ÷ 150 | 90.000 |

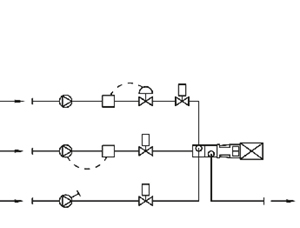

PI&D basic installation of the in-line mixer LIVAK, can work in recirculation on one or several tanks. Shown are the feed of liquid components to the mixer head or reservoir, and the feed of solid components to the reservoir.

Boosting existing installations

When more intense agitation is required in an existing installation, it is very advantageous to install a LIVAK in recirculation over the tank instead of modifying the existing agitator.

Emulsifier

The LIVAK EMULSIFIER produces air-free emulsions with small drop size and high stability. Combining it with our DOUBLE-FLOW or HELICOIDAL ANCHOR vane agitators with scrapers reduces production and heat exchange times.

PI&D basic installation of the LIVAK in-line mixer in continuous operation. Continuous dosing of three liquid components to the in-line mixer head is shown.

Supply possibilities

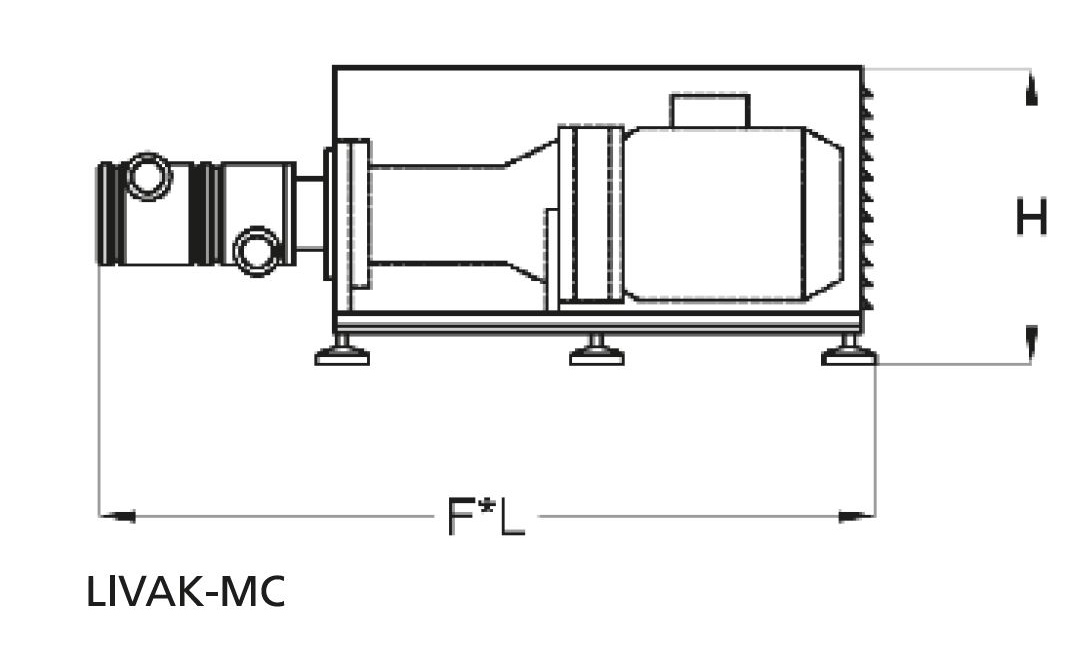

Dimensions

| Types | H (mm) | L (mm) | F (mm) |

| LIVAK 00 | 250 | 400 | 380 |

| LIVAK 01 | 450 | 900 | 300 |

| LIVAK 1 | 500 | 1.200 | 380 |

| LIVAK 2 | 650 | 1.450 | 450 |

| LIVAK 3 | 690 | 1.500 | 450 |

| LIVAK 4 | 800 | 2.200 | 680 |