In-line solid-liquid mixer with direct addition of the solid to the mixer head.

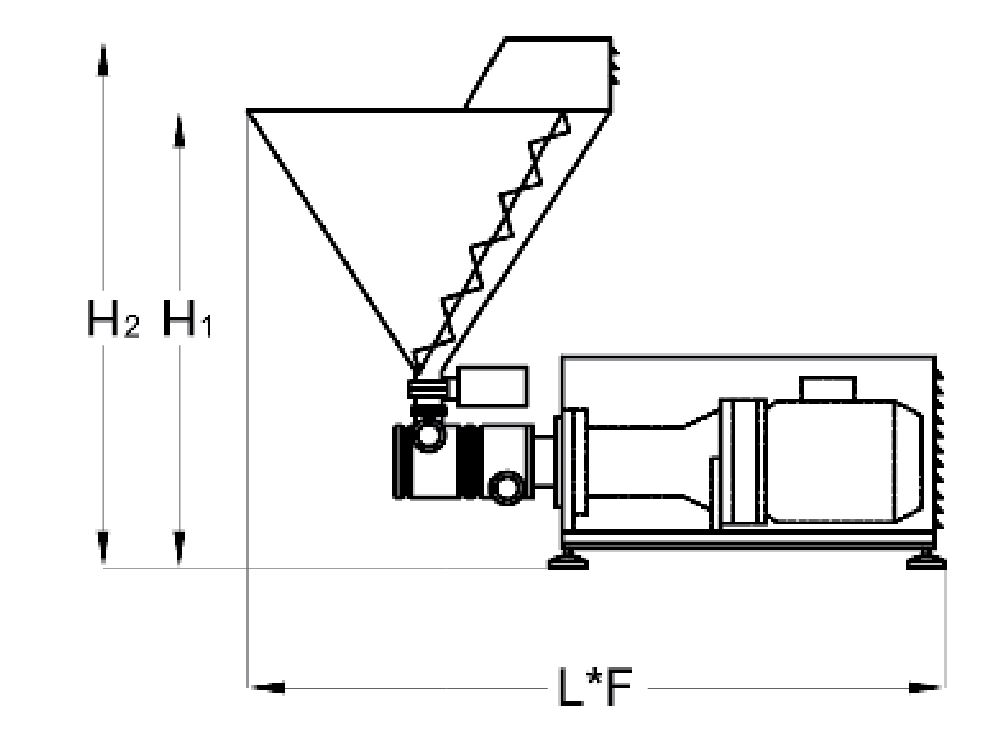

ALVAK with TC hopper equipped with table to support sacks, the operator works comfortably and ergonomically

ALVAK designed according to EHEDG. TC hopper, equipped with a table to support sacks and C-shaped legs, which allow the hopper to be moved to the washing area.

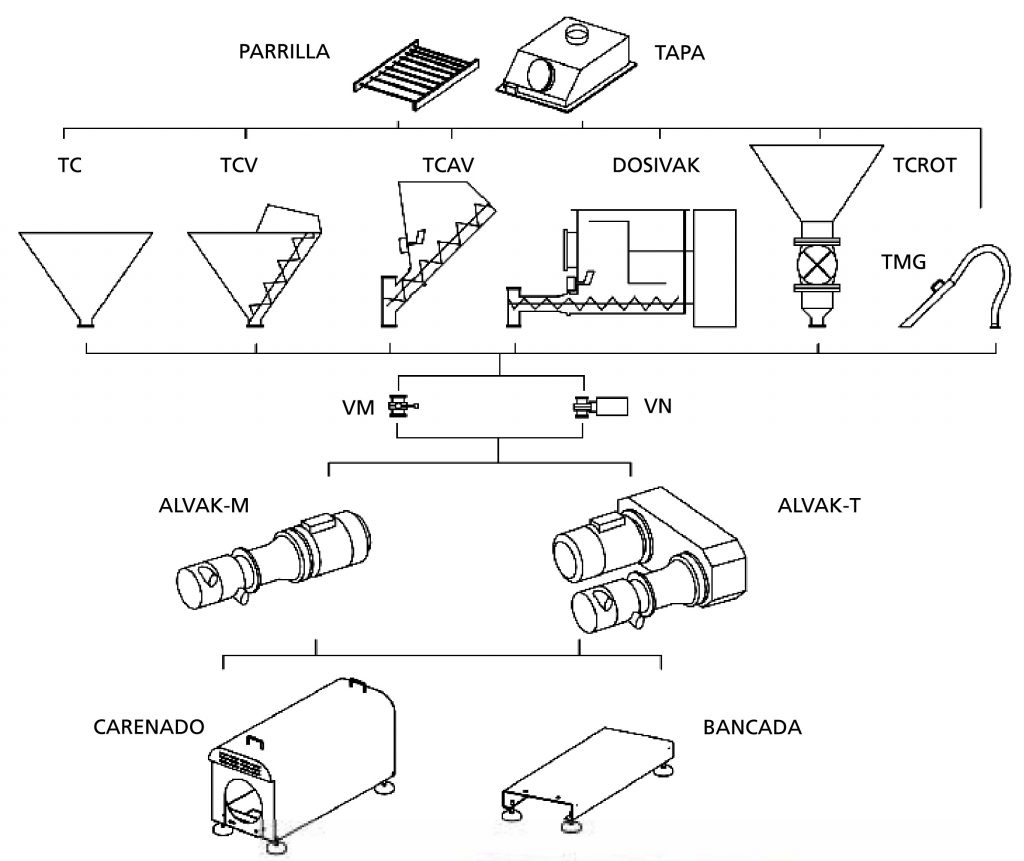

COMPONENTS

Powdered, crystalline or granulated solids directly to the mixer head + liquids

SOLIDS CONCENTRATION

≤ 80%, according to product

PRODUCT VISCOSITY

Medium-Low

SOLID FLOW RATE

≤ 15.000 kg/h

MIX FLOW RATE

≤ 90.000 l/h

Technical characteristics

| Types | Power ALVAK (kW) |

Power hoppers (kW) |

Liquid connection (DN) |

Maximum mixing flow (l/h) |

Maximum solid flow (Kg/h) |

| ALVAK 00 | 0,55 ÷ 1,5 | – | 15 ÷ 25 | 500 | 100 |

| ALVAK 01 | 2,2 ÷ 5,5 | 2,2 ÷ 5,5 | 25 ÷ 40 | 10.000 | 1.500 |

| ALVAK 1 | 4 ÷ 15 | 2,2 ÷ 5,5 | 40 ÷ 65 | 25.000 | 3.000 |

| ALVAK 2 | 7,5 ÷ 22 | 3 ÷ 7,5 | 65 ÷ 80 | 40.000 | 5.000 |

| ALVAK 3 | 15 ÷ 37 | 3 ÷ 7,5 | 65 ÷ 100 | 60.000 | 8.000 |

| ALVAK 4 | 22 ÷ 55 | 4 ÷ 10 | 80 ÷ 150 | 90.000 | 15.000 |

*The maximum mixing flows depend on the required pressure. VAK KIMSA, S.A. reserves the right to modify these data.

Solids feeding

The feed of solids to the hopper of ALVAK mixers can be: by sacks, big-bag, worm screw, rotary valve, pneumatic transport… manually or automatically.

Feeding of solids to the hopper of the ALVAK in-line mixer from big-bag.

ALVAK with TCV hopper automatically fed by rotary valve, from the weighing hopper where the recipes to be manufactured are elaborated.

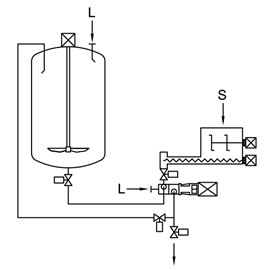

Automation

For automatic operation, ALVAK mixers are supplied with pneumatic valve, minimum and maximum levels in the hopper and electrical cabinet. Operations are performed by means of an independent PLC or under factory control supervision.