Quality

VAK KIMSA has a Quality Management System in accordance with the requirements of the standard UNE-EN ISO 9001:2015

Download here our ISO 9001:2015 certificate

VAK KIMSA’s motto is quality first and foremost and total customer satisfaction.

Our success depends on constant dedication to these principles. Quality includes every aspect of VAK KIMSA, from safety to the final destination of the product.

Principles:

The primary objective is to satisfy 100% of the expectations that the customer has of our product.

The customer is the one who defines the quality requirements for his specific use. Together we agree on measurable specifications for our products to meet your needs.

All our raw materials are measured under established quality standards and each supplier must meet quality standards.

The relationships with our customers and suppliers are characterized by cooperation and open communication, we are committed to respond enthusiastically and professionally to any need expressed by them.

Quality policy

Check our ISO 9001 Quality Policy here.

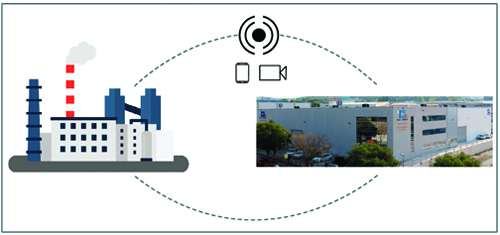

Visual technical support service

In order to fulfill your needs, we offer the new visual technical support service.

The service consists in doing a video connection, through a mobile phone or tablet camera, remotely, to be able to visualize the scope of the incident, and our technicians will give you indications to solve them, via telephone, without the need of displacement to your factory and being totally assisted.

This option is also available for start-ups, technical queries and maintenance.

We are a certified supply chain company of essential companies and we continue to work for the good of all!

After-sales

Technical advice regarding the installation or Installation

Our technicians and mechanics are at your disposal:

- We come to your factory for technical advice and training so that you can install your agitator or mixer.

- We carry out the assembly in your factory.

Technical assistance for commissioning

If you would like our support and advice during commissioning, our SAT technical department is at your disposal.

Preventive maintenance

By means of the preventive maintenance of your equipment, you will be able to maintain your facilities always in optimal conditions, avoiding also the setback that supposes a breakdown caused by the deterioration of some of the elements of wear, with the consequent saving of time and money. With our SAT department you can schedule annual maintenance days in your factory.

Preventive maintenance

By means of the preventive maintenance of your equipment, you will be able to maintain your facilities always in optimal conditions, avoiding also the setback that supposes a breakdown caused by the deterioration of some of the elements of wear, with the consequent saving of time and money. With our SAT department you can schedule annual maintenance days in your factory.

Repairs

With an acquired experience since 1972 and more than 21,000 equipments in the market, we have the necessary competences to solve any operative problem, of operation or of pieces that can have related to our agitators and mixers.

Reforms and modernizations

Modernization services allow you to extend the useful life of your equipment, adapting it to your new needs and improving its safety.

Thanks to our experience and technological knowledge, we can undertake all types of modernization projects, both in agitation equipment and in line mixing.

Reforms and modernizations

Modernization services allow you to extend the useful life of your equipment, adapting it to your new needs and improving its safety.

Thanks to our experience and technological knowledge, we can undertake all types of modernization projects, both in agitation equipment and in line mixing.

Spare parts

Our SAT department will be able to supply spare parts to all our customers all over the world, with the highest quality assured and in a very short time. We have traceability of all equipment manufactured from unit #1. Buying the spare part from VAK KIMSA guarantees that it is original and with the manufacturer’s warranty.

Training for production and maintenance

30-45′ online monographic courses on mechanical concepts of agitators and in-line mixers, to ensure correct installation, commissioning, operation and maintenance.

Training for production and maintenance

30-45′ online monographic courses on mechanical concepts of agitators and in-line mixers, to ensure correct installation, commissioning, operation and maintenance.